ParaThermic® High-Heat Transfer (HHT) Batteries:

A Paradigm Shift for Battery Thermal Management

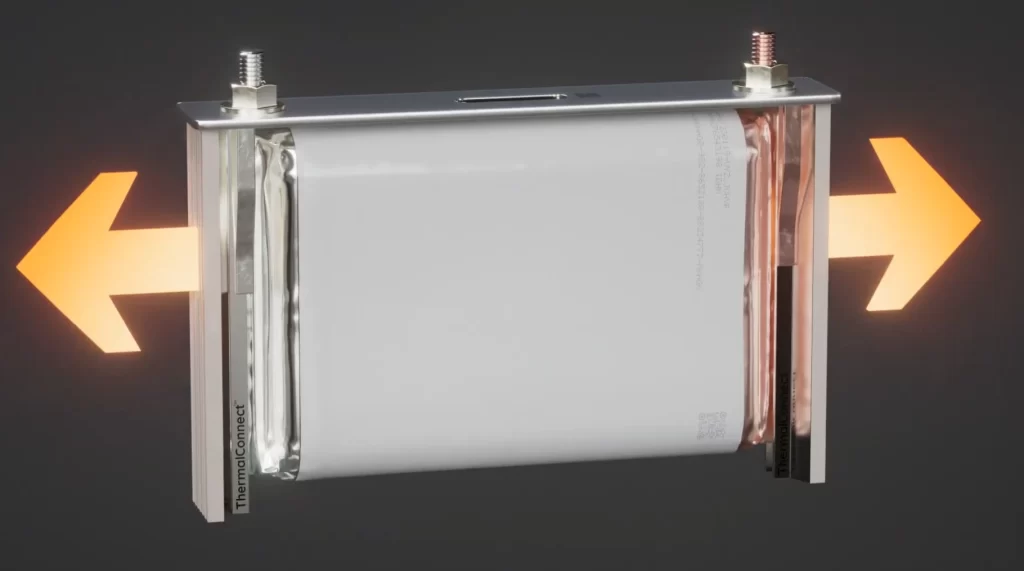

ParaThermic® High-Heat Transfer (HHT) Battery Architecture

ParaThermic® High Heat Transfer (HHT) battery architecture represents a breakthrough in electric vehicle battery thermal management, battery cooling technology, and battery design.

By reengineering the internal structure of the cell, HHT batteries remove the internal heat bottlenecks that limit performance, safety, and battery life.

This innovation enables breakthrough gains in the key performance metrics customers care about most, including:

- Safety – Thermal runaway mitigation (delay or prevention)

- Faster Charging – Thermally supports extreme fast charging

- Cold Weather Performance – Reduced power and range loss

- Range Improvement – Weight reduction, Lower BTMS power consumption, enabler for higher energy density

- Cost – Pack size reduction, simpler battery pack design

- Reliability – Substantial gains in battery life

To understand ParaThermic® High-Heat Transfer (HHT) battery architecture, we first must recognize the limits of today’s batteries.

The Challenge

Electric vehicles are reaching a point where further improvements in safety, charging speed, cold weather performance, battery life, cost reduction, and reliability, all depend on better battery thermal management inside the battery.

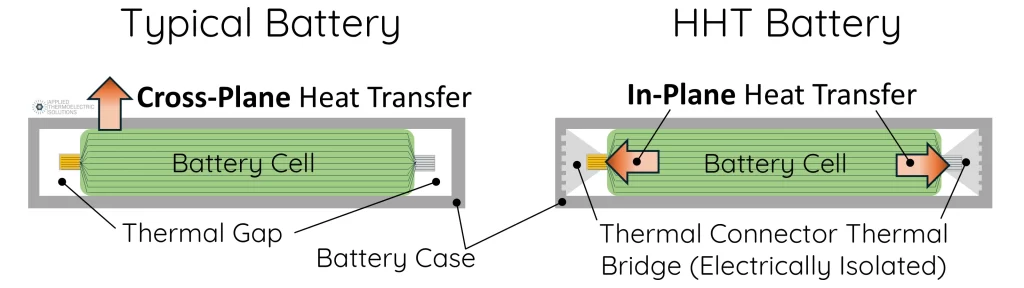

Current battery thermal management systems remove heat from the battery surface, but it must still travel through slow internal pathways within the cell. These internal thermal bottlenecks create a limit that affects real world vehicle performance, even with advanced EV battery cooling systems.

Even the most advanced battery cooling system cannot overcome this limitation

ParaThermic® batteries are specifically designed to solve this problem.

Why Traditional Cooling Has Reached Its Limits

Cooling systems have become more advanced, but their improvement relies on further lowering the battery surface temperature to pull more heat from the interior. Once the allowable temperature difference in the cell is reached, the battery cannot be cooled any harder without increasing degradation or reducing safety margins.

At that point, the internal heat transfer pathway becomes the bottleneck. External cooling can only go so far when the interior of the cell limits how quickly heat can escape, restricting the capability of common battery thermal management systems.

This internal limit is being reached now, and it is preventing further gains in every major category of EV performance.

This is where the new ParaThermic® architecture changes everything.

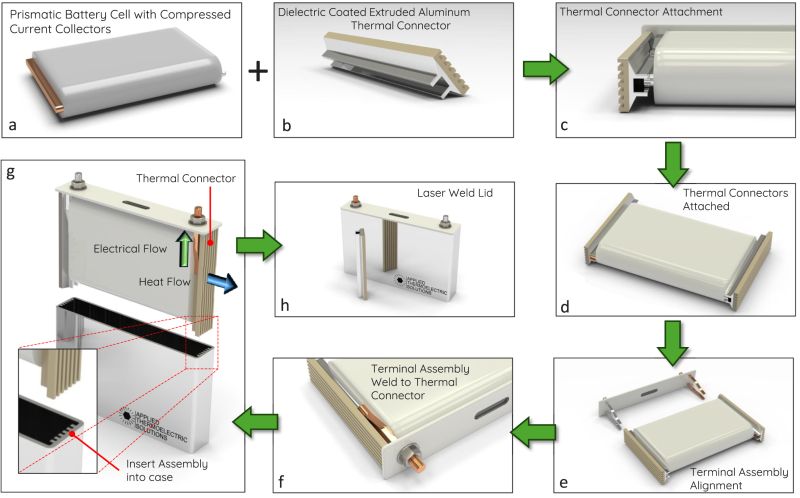

How ParaThermic® Batteries Work

Heat inside a battery moves much faster and more uniformly along the plane of the internal layers than through the thickness of those layers. ParaThermic® batteries are designed to take advantage of this.

The architecture enables heat to flow in these faster paths, but also shortens the distance it must travel, and uses thermally conductive bridges to move heat efficiently to the outer case.

Engineered interfaces further improve heat flow from the interior to the battery pack cooling system, including air cooling, liquid cooling, refrigerant cooling, and immersion cooling.

The result is a battery that moves heat far more effectively from the inside out, enabling far better battery heat management under real operating conditions.

These internal improvements enable real-world performance gains that customers and manufacturers care about.

Performance Advantages

- Up to 20 times higher heat removal capability compared to existing batteries.

- Supports the thermal load required for a 3.5 minute full charge

- Strong thermal runaway delay or mitigation that improves the thermal management of lithium ion batteries

- Warm up times reduced to 1 to 8 minutes in cold conditions

- More than three times longer battery life due to improved battery temperature control

- Up to 20 percent reduction in pack size and weight

- Lower cooling system power consumption and improved range

- Thermal capability to enable low cost air cooled battery 15-minute charging

But these performance metrics matter only if the product can be reliably built and integrated. ParaThermic® batteries meets that test.

Practicality and Integration

ParaThermic® batteries use conventional materials and manufacturing techniques. They work with existing lithium ion chemistries and work with all cell formats.

The architecture supports base cooling, integrates with the conventional side-cooled battery designs already used in vehicles, and also works with advanced side-cooling systems such as VoltaTherm®.

It can be integrated into any cooling system type, including air cooling, liquid cooling, refrigerant cooling, immersion cooling, and thermoelectric cooling, improving overall battery pack thermal management performance.

The underlying thermal principles have been validated through modeling and published research.

For those ready to dive deeper or begin evaluating applications, these resources will guide you

Next Steps

- Download the ParaThermic 1-page overview

- Contact our team for a detailed discussion

- Read the technical deep dive

- Download the peer reviewed research paper