What is solid-state thermoelectric technology and how does it work?

Solid-state thermoelectric heating and cooling technology is also known as Peltier cooling. Sometimes it is abbreviated TEC (Thermo-Electric Cooling) and TED (Thermo-Electric Device) technology.

Solid-state thermoelectric devices use electricity and semiconductors to produce cooling and heating. As opposed to refrigerants used in conventional cooling systems.

The magnitude of heat flow is adjustable by varying the amount of electrical current.

Why solid-state thermoelectric thermal management?

With recent materials science advances, solid-state thermoelectric heating and cooling has started to transform the heating and cooling and thermal management industry in a similar way that solid-state electronics has transformed the electronics industry and our world.

9 Advantages of Solid-State Thermoelectric Thermal Management Technology

1. Solid-state

There are no moving parts. This means solid-state thermoelectric technology has higher reliability which leads to happier customers and increased profits.

2. No Greenhouse Gases Required

Unlike compressor based conventional cooling systems, solid-state thermoelectric heating and cooling does not require expensive refrigerants.

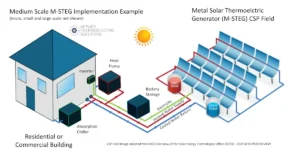

3. Scalability

Systems can be scaled from less than one watt of cooling power up to kilowatts.

The ability to scale thermoelectric thermal management systems offers a much wider range of market share opportunities compared with systems that are not scalable.

Common components can be used for large and small scale systems. This results in reduced manufacturing and design costs.

4. Efficiency

Solid-state systems have the potential to operate at high efficiency (COP), depending on the application and design.

Further efficiency gains can be obtained by using the devices for spot or distributed cooling rather than cooling an entire enclosure which is common with conventional technology.

Customers want efficient products.

5. Cooling and Heating in One Device

Unlike compressor based systems, solid-state devices can heat and cool from the same device with a simple switch in the direction of electrical current.

This leads to simpler designs with less parts to break and fewer warranty claims from customers

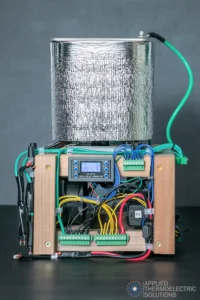

Pictured above, a Solid-State Thermoelectric Heating and Cooling Device

6. Precise Temperature Control

Solid-state thermoelectric devices excel at precise temperature control.

This makes possible products that are out of reach with conventional compressor based systems that are more difficult to control.

7. Below Ambient Cooling

The ability to control temperature to below ambient allows food to last longer, drinks to feel colder, batteries to last longer, CPU’s to run cooler and at higher performance, better human thermal comfort, longer life electronics and safer medicine storage.

All of these result in benefits customers need and want.

8. Silent Operation

With solid-state technology, there will be no noise complaints as there are with conventional vibrating compressor technology.

Customers will leave better reviews for your product.

9. Mountable in Any Orientation

Since there is no refrigerant or moving parts, solid-state thermoelectric devices can be mounted in any orientation.

This leads to greater design flexibility and a wider range of applications that can keep up with your creativity.

Applications

We believe there are limitless applications for solid-state heating and cooling. Below are just a few that are currently in use or being investigated.

- Solid-State refrigerators

- Heated and cooled mattresses

- Wine bottle coolers

- Telecom devices

- Thermal therapy devices

- Electronics and Peltier CPU cooling

- Thermoelectric battery thermal management

- Electronics kiosk cooling

- Zonal thermoelectric climate control

- Heated and cooled vehicle seats

- Beverage heating and cooling

- Thermoelectric Office chairs

- Mini In-vehicle Peltier refrigerators

5 Responses

Can this replace gas central heating?

Arthur, Thank you for the question. If we evaluate whether something can be replaced, there are many different metrics to consider. Such as equipment cost, fuel/electricity cost, controllability, distribution, and many more. Thermoelectrics can achieve a coefficient of performance (COP) greater than one and can be used for zonal heating rather than heating a large area. So under some circumstances thermoelectrics may be more efficient than gas heating. It would depend on the situation. This is something we can evaluate for you based on your unique situation.

Always been interested in peltier effect. Been electronic tech. For 36 years. Always wanted to experiment scaling it up or down. I wanted to live off grid. Solar power and solid state. There has to be a happy ending in the equation.

Does any company actually sell heaters yet?

Hi, thank you for your question. It sounds like you’re referring to thermoelectric heating, as mentioned in the previous comments. Thermoelectric modules can indeed be used for both heating and cooling by reversing the direction of electrical current. So, any company that sells thermoelectric modules is effectively selling a device that can function as both a heater and a cooler.

One of the advantages of using a thermoelectric module for heating over a standard resistive heater is its potential for higher efficiency. While a standard resistive heater operates at 100% efficiency (meaning all the power input is converted into heat), a thermoelectric module can achieve efficiencies greater than 100%. This is because, in addition to converting electrical energy into heat, the module also “pumps” or moves extra heat from the cold side of the module. Of course, the overall efficiency depends on the specific application and operating environment.

I hope this helps clarify things! Let me know if you have more questions.