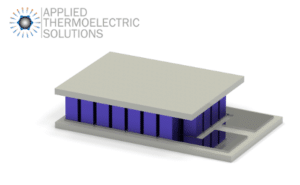

To understand how heat is transported in a Peltier module, it is necessary to understand the construction of a Peltier module.

A semiconductor couple is the basic building block of a thermoelectric / Peltier module. A couple consists of one p-type and one n-type semiconductor block connected by a metallic strip.

These semiconductor blocks are also called thermoelements. The p and n semiconductor blocks are connected electrically in series and thermally in parallel.

The metal strip serves as a junction between the two semiconductors. When DC current is passed through the couple, heat is absorbed at the cold side junction and heat is released at the hot side junction.

To create a Peltier module, many couples are placed electrically in series and sandwiched between substrates that are generally ceramic.

The cooling capacity scales directly proportional to number of couples in the module.

In addition to connecting the couples electrically in series, sometimes the couples are connected electrically in parallel or series-parallel to reduce the electrical resistance of the module.

How is heat transported in a Peltier Module?

The heat transport in a Peltier module can explained with charge carrier analysis.

In thermoelectric materials, charge carriers are electrons and holes.

Electrons carry a negative charge and holes carry a positive charge. In n-type materials, the charge carriers are electrons and in p-type materials, the charge carriers are holes.

Holes are empty spaces in a crystal lattice that an electron could occupy.

These holes are free to move about within the lattice. When charge carriers move they take heat with them.

Energy absorbed and liberated can be accounted for by a change in energy level of electrons. Electrons that move to a higher energy level absorb heat and electrons that move to a lower energy level release heat.

The material characteristics and polarity of the DC source relative to the p and n arrangement makes possible energy absorption and release in a controlled manner.

4 Responses

Why don’t you use a transistor type Peltier module to reduce voltage at the heat dissipating end and

I ask you a question. What if a transistor could generate heat only and if we reverse engineer the same transistor to a cold dissipating transistor it would only dissipate cold and no heat will be generated.

Tim, Interesting idea. I am not familiar with the concept. Thank you for posting.

With continued use of a thermoelectric element are holes regenerated with 100% efficiency or does the performance decline with time? For heating applications how does the heat generated by a thermoelectric device compare to electrical resistive heating for the same power consumption?

Thank you, Dr. Rowlands, for your thoughtful questions. I’m happy to share some insights.

With continued use of a thermoelectric element are holes regenerated with 100% efficiency or does the performance decline with time?

In thermoelectric cooling and thermoelectric power generation, a hole is simply the absence of an electron when an electron moves from the valence band to the conduction band. The material does not have a limited supply of holes and they are not “used up” during operation. Charge carriers continually move within the semiconductor lattice, so a thermoelectric module does not lose performance because of hole depletion.

Any long-term performance change in a thermoelectric cooler or thermoelectric generator is usually caused by material diffusion, thermal cycling fatigue, or wear at solder and contact interfaces. High quality thermoelectric modules operated within their temperature limits typically show very little degradation over time. This is one reason proper design, modeling, and thermal management are important when integrating thermoelectric technology into a system.

For heating applications how does the heat generated by a thermoelectric device compare to electrical resistive heating for the same power consumption?

For heating applications, the heat output from a thermoelectric module and a resistive heater will be the same if the electrical resistance, voltage, and current are the same. Both convert electrical power into resistive (Joule) heating. The difference is that a thermoelectric module can also pump heat from its cold side to its hot side. This added pumped heat can raise the total heat output and give the system a coefficient of performance greater than one. Under the right operating conditions, this can make thermoelectric heating more effective than simple resistive heating.