The Author – Founder and CTO

Alfred Piggott is the Founder and CTO of Applied Thermoelectric Solutions, specializing in thermoelectrics, battery thermal management, and energy conversion. With more than 30 years of engineering experience, he develops advanced cooling, power generation, and high-heat-transfer battery technologies. Alfred holds multiple patents, has published award-winning research, and shares practical insights from ongoing modeling, system development, and prototype build work.

Key Takeaways

- Thermoelectric generators enable solid-state solar power without photovoltaics:

Metallic solar thermoelectric generators convert solar heat directly into electricity using the Seebeck effect, enabling solid-state power generation without, moving parts, or fragile photovoltaic panels. - System-level efficiency can exceed device-level electrical efficiency through CHP:

While the electrical conversion efficiency of thermoelectric generators is lower than that of photovoltaic cells, M-STEG systems can achieve higher system-level efficiency by enabling combined heat and power (CHP), increasing total energy utilization. - Cost per watt and manufacturability are primary economic drivers:

Low material costs, simple manufacturing, and modular architectures allow M-STEG systems to achieve competitive cost-per-watt economics in applications where durability, scalability, and lifecycle cost matter. - Material selection improves sustainability and supply-chain resilience:

Metallic thermoelectric materials offer recyclability, reduced environmental impact, and lower exposure to constrained global supply chains compared to many conventional solar technologies. - Modular scalability enables flexible deployment across applications:

M-STEG systems can recover both electrical power and usable thermal energy from high-temperature radiant heat sources, including industrial equipment such as furnaces or hot steel, as well as from parabolic trough collectors that deliver concentrated solar radiation.

Solar Thermoelectric Generator Case Study: Evaluating Metallic TEGs as a Commercial Solid-State Power Solution

Turning solar heat into electricity without photovoltaics

Solar power generation is dominated by photovoltaic technology, yet PV systems face growing challenges related to material costs, supply-chain risk, recyclability, grid integration, environmental concerns and long-term sustainability. In response to these challenges, Applied Thermoelectric Solutions LLC was engaged by STEMero to evaluate an alternative approach to solar energy conversion using thermoelectric generators. Rather than relying on conventional semiconductor-based thermoelectric generators, this work focused on a metallic implementation, referred to here as Metallic Solar Thermoelectric Generators (M-STEGs).

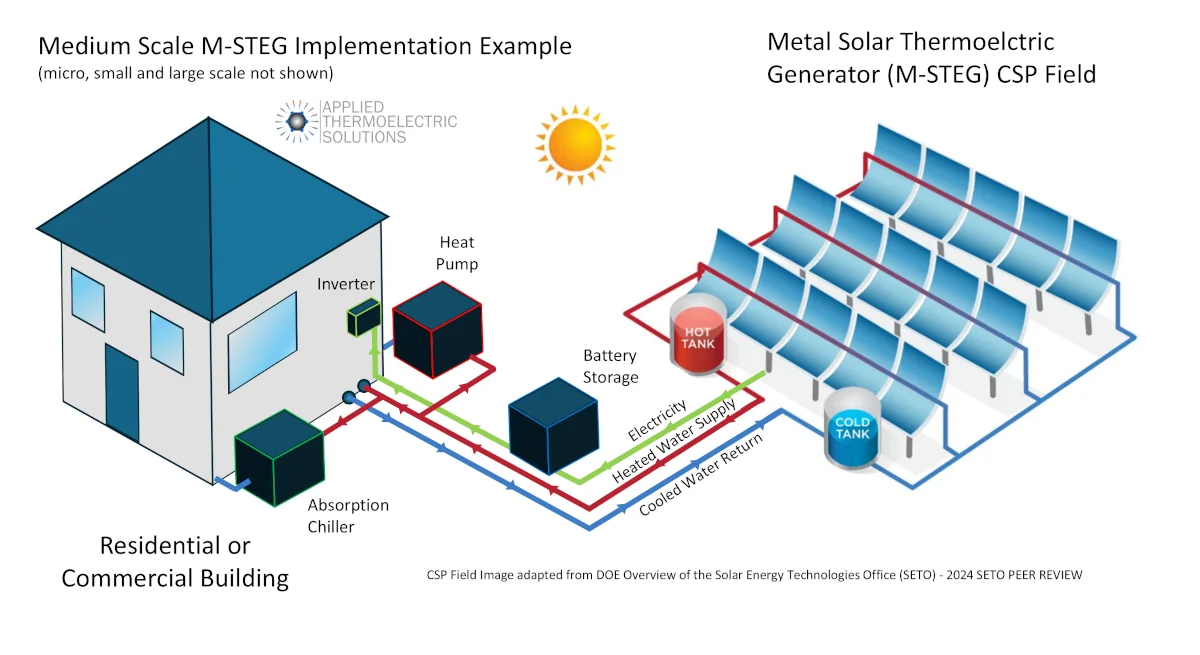

A metallic solar thermoelectric generator (M-STEG) is a solid-state energy system that converts concentrated solar heat directly into electricity using metallic conductors rather than semiconductor thermoelectric materials.

This analysis is based on modeling, trade-space evaluation, and system-level feasibility work conducted by Applied Thermoelectric Solutions for an external client.

Technical Background

While this article focuses on system-level feasibility and commercial considerations, a separate overview explains the fundamental operating principles, material behavior, and performance tradeoffs of thermoelectric generators in greater detail.

Most thermoelectric generators rely on semiconductor materials that offer higher electrical conversion efficiency than metallic materials. However, this efficiency advantage often comes at the expense of cost, scalability, durability, recyclability, and supply-chain resilience. In contrast, metallic thermoelectric generators prioritize abundant, mechanically robust, and recyclable materials, shifting the design focus toward system-level economics and long-term deployability rather than device-level efficiency alone.

This case study summarizes how thermoelectric generator technology, traditionally viewed as a niche solution, can become a commercially viable solid-state power generator when evaluated through cost per watt, scalability, durability, and total energy utilization rather than electrical conversion efficiency alone.

The commercial problem with conventional solar power

Traditional solar photovoltaic systems achieve relatively high electrical conversion efficiency, but they rely on complex semiconductor manufacturing, fragile global supply chains, and materials that are difficult to recycle. In addition, PV systems generate electricity only, rejecting a large fraction of incoming solar energy as waste heat.

For many industrial, infrastructure, and utility-scale applications, cost per installed watt, system durability, supply-chain security, and total usable energy matter more than peak electrical efficiency.

These constraints create an opportunity for thermoelectric power generators that convert heat directly into electricity using solid-state materials and the Seebeck effect, while simultaneously enabling the recovery of useful thermal energy.

Project objective

The objective of this feasibility study was not to compete directly with photovoltaic systems on electrical conversion efficiency. Instead, the goal was to determine whether metallic thermoelectric generators integrated with concentrated solar power (CSP) could:

- Deliver competitive cost per watt

- Scale from small systems to utility-relevant power levels

- Use abundant, recyclable metallic materials

- Reduce supply-chain and geopolitical risk

- Enable combined heat and power (CHP) operation

- Compete favorably with PV at the system level

Study approach

The project was conducted in two structured phases.

Phase 1: Technology landscape and material evaluation

A broad landscape study was performed across metallic thermoelectric materials and conductor geometries used to form thermoelectric junctions.

In this context, wire geometry refers to the diameter, length, and arrangement of metallic conductors that determine electrical resistance, current density, heat flow, and manufacturability.

Key parameters evaluated included power output, voltage, material cost, electrical current, cooling requirements, and environmental impact. This phase identified promising material and geometry combinations while revealing practical challenges associated with extreme operating points.

Phase 2: Application of real-world engineering constraints

The second phase applied practical limits related to:

- Electrical current levels

- Cooling heat-flux capability

- Available solar heat flux from realistic concentration systems

- Cost-per-watt benchmarks comparable to commercial photovoltaic systems

Configurations requiring extreme electrical currents, impractical cooling approaches, or unrealistic solar concentration were eliminated or deprioritized.

This shifted the optimal design space toward conductor geometries that balance performance, cost, manufacturability, and system complexity rather than simply

minimizing material cost per watt.

Key findings with commercial relevance

Lower efficiency does not imply lower value

While metallic solar thermoelectric generators exhibit lower electrical conversion efficiency than photovoltaic panels, material costs per watt were shown to be highly competitive. When evaluated as a solid-state power generation system, rather than a single-metric efficiency device, M-STEGs demonstrated strong commercial potential.

Chromel-Constantan emerged as a leading candidate

Among the metallic thermoelectric materials evaluated, Chromel-Constantan provided the most favorable balance of voltage output, cost, manufacturability, and scalability. Other metal pairs were found to require substantially higher thermal concentration or cooling area expansion, increasing overall system complexity.

System design dominates economics

The study demonstrated that the lowest material cost-per-watt geometries often impose the highest demands on cooling performance, solar concentration, and electrical infrastructure. In many cases, selecting slightly higher material cost-per-watt geometries results in lower total system cost, improved reliability, and reduced parasitic losses.

Sustainability and supply-chain advantages

Metallic thermoelectric generators use recyclable, widely available materials and avoid many of the environmental and end-of-life challenges associated with photovoltaic panels. The reliance on metals rather than specialized semiconductors significantly reduces supply-chain risk.

Client Perspective

“As the CEO of STEMero, I conceived the idea of evaluating metallic solar thermoelectric generators as an alternative solar power pathway and worked with Applied Thermoelectric Solutions on a feasibility study to assess its technical and commercial viability. ATS helped frame the critical technical and economic questions, assess material cost and system-level performance, and identify realistic pathways toward prototype development and external funding. Their ability to integrate engineering analysis with commercial considerations was essential in moving this concept from an initial idea to actionable next steps.”

— Diane Mero, CEO, STEMero

Reframing efficiency: electrical efficiency vs system efficiency

It is important to clarify how efficiency is evaluated when comparing metallic solar thermoelectric generators to photovoltaic systems.

From a pure electrical conversion standpoint, photovoltaic panels convert a higher fraction of solar irradiance into electricity. This study did not attempt to compete with PV on that metric alone.

Instead, the focus was on overall system efficiency and energy utilization.

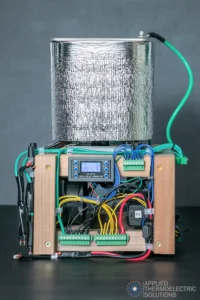

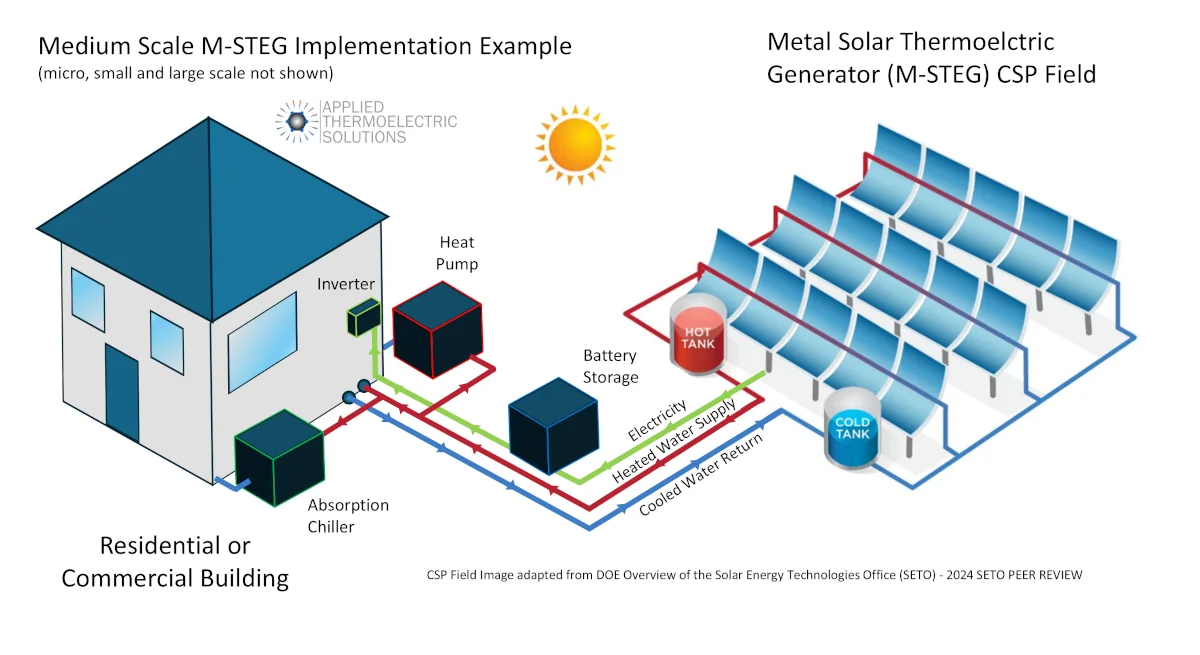

Metallic solar thermoelectric generators inherently operate as combined heat and power (CHP) systems. In addition to generating electricity through the Seebeck effect, M-STEG systems simultaneously produce useful thermal energy in the form of heated water or steam. When both electrical output and recovered thermal energy are considered, the total usable energy extracted from the solar resource can exceed that of photovoltaic systems, which discard most thermal energy as waste heat.

This distinction is critical in applications where thermal energy has value, such as industrial processes, district heating, absorption cooling, hybrid heat-pump systems, and commercial or off-grid greenhouses.

Strategic impact

This feasibility study demonstrates that metallic solar thermoelectric generators should not be evaluated solely as electrical power devices. When viewed as solid-state combined heat and power systems, M-STEG technology offers a compelling alternative in applications where durability, sustainability, and total energy utilization outweigh peak electrical efficiency.

The results indicate strong potential for deployment in:

- Concentrated solar thermal installations

- Industrial facilities requiring both heat and electricity

- Regions facing PV supply-chain or recycling constraints

- Infrastructure applications where reliability and long service life are critical

Next steps toward commercialization

Based on the results of this study, the next phase of development will focus on:

- Refining M-STEG designs for manufacturability

- System-level optimization of thermal concentration and cooling

- Prototype development and pilot-scale validation

- Identification of early-adopter markets and strategic partners

The findings from this feasibility analysis provide a solid technical and commercial foundation for advancing metallic solar thermoelectric generators from modeling to deployable energy systems.

Why this matters

Thermoelectric generators are no longer limited to niche or laboratory applications. When applied strategically, metallic solar thermoelectric generators offer a durable, scalable, and supply-resilient approach to renewable energy generation that complements, rather than replaces, conventional solar technologies.

For organizations exploring thermal energy harvesting, solid-state power generation, solid-state cooling, high-heat transfer technologies, or combined heat and power solutions, this case study demonstrates a credible and commercially grounded pathway forward.

This case study is intended for organizations evaluating non-photovoltaic solar power technologies at the system level.

Explore Whether a Thermoelectric Generator Makes Sense for Your Application

Work with Applied Thermoelectric Solutions to evaluate system-level efficiency, energy utilization, cost-per-watt tradeoffs, and integration pathways for your specific application.

Related Work

Explore additional thermoelectric generator, thermal management, and energy system projects completed by Applied Thermoelectric Solutions.

Frequently Asked Questions

How does a thermoelectric generator differ from a photovoltaic solar panel?

A thermoelectric generator converts heat directly into electricity using the Seebeck effect, while photovoltaic panels convert light into electricity. Thermoelectric systems are solid-state, can utilize heat rather than direct sunlight, and can enable combined heat and power configurations.

Why consider thermoelectric generators if their electrical efficiency is lower than PV?

While device-level electrical efficiency is lower, thermoelectric generator systems can achieve higher system-level efficiency when both electrical output and useful thermal energy are captured through combined heat and power (CHP).

What applications are best suited for thermoelectric generators?

Thermoelectric generators are well suited for applications where heat is already available or valuable, such as solar thermal systems, industrial waste heat recovery, remote power generation, and infrastructure requiring durable, low-maintenance power sources.

Are metallic thermoelectric generators commercially viable today?

Thermoelectric generators can be commercially viable when one or more of their inherent advantages align with the requirements of a specific application. These advantages can include solid-state reliability with no moving parts, long operational life, quiet operation, wide fuel flexibility, scalability across a broad power range, and the ability to operate in demanding environments such as extreme temperatures, high-G, or zero-G conditions. In such cases, simplicity, durability, and system-level value, rather than peak electrical efficiency alone, determine whether a thermoelectric generator represents a viable product.

How does Applied Thermoelectric Solutions support thermoelectric generator projects?

Applied Thermoelectric Solutions provides feasibility studies, system-level modeling, design optimization, and commercialization support to help organizations evaluate, design, and deploy thermoelectric generator systems tailored to their specific applications.

Links that May Interest You

Did You Like This Post?

We would greatly appreciate it if you could leave a comment to let us know your thoughts on this post.

Your feedback and suggestions are highly valued and we welcome all comments and tips.

Thank you for taking the time to share your input with us.