The Author – Founder and CTO

Alfred Piggott is the Founder and CTO of Applied Thermoelectric Solutions, specializing in thermoelectrics, battery thermal management, and energy conversion. With more than 30 years of engineering experience, he develops advanced cooling, power generation, and high-heat-transfer battery technologies. Alfred holds multiple patents, has published award-winning research, and shares practical insights from ongoing modeling, system development, and prototype build work.

Table of Contents

Don’t need the full engineering deep dive?

Prefer the high-level version instead?

Introduction

Customers expect electric vehicles with higher operational performance, which drives significant battery improvements, including:

- Less waiting through fast battery charging

- Increased vehicle range through higher energy density

- Greater reliability through longer battery life

- More affordable vehicles through size and weight reductions

- Better cold-weather performance through faster battery warmup

- Increased safety through lower thermal runaway risk

These may appear to be small, incremental vehicle-level requirements, but they drive major changes inside the battery. The surprising truth is that every one of these performance expectations is fundamentally limited by battery thermal management.

Advancements in batteries and battery thermal management have enabled the electric vehicles we have today. However, improvements in external cooling technologies are no longer sufficient to transform battery thermal management. Even advanced methods such as immersion cooling, phase change materials, or pulsating heat pipes cannot overcome the physical heat transfer limits inside the battery cell.

Meeting future EV performance targets requires a transformative improvement in thermal capabilities. A complete shift in how we think about battery thermal management is needed.

In the sections that follow, we introduce a research-driven framework for next-generation battery thermal management design, explain the physical limits that constrain current systems, and present a solution that has the potential to transform battery performance and overall EV capability.

Who This Article Is For

This article is written for EV battery engineers, thermal management specialists, cell designers, researchers, and OEM teams who want a deeper understanding of the physics that limit battery thermal management today.

It is also valuable for those working in fast charging, battery safety, cold-weather performance, battery pack integration, or next-generation EV platform development. Professionals from related fields, as well as anyone interested in the engineering behind next-generation battery thermal management, will benefit from the framework and insights presented here.

HHT Battery Summary Download

Get the one-page high-level summary of ParaThermic High-Heat Transfer battery architecture. This PDF includes the core engineering principles, performance advantages, and the design framework that enables next-generation battery thermal management.

Key Takeaways

- Battery thermal management is essential for EV performance, safety, and longevity

Effective battery thermal management is critical for maintaining performance, extending battery life, ensuring safety, and enabling fast charging. As EV customers expect faster charging, better cold-weather performance, higher range, improved safety, and lower cost, thermal management has become one of the most important engineering challenges in modern EV design.

- Traditional battery thermal management is reaching its physical limits

Advances in cooling technologies have helped EVs reach today’s performance levels, but transformative improvements require far more heat removal, tighter temperature uniformity, faster thermal response, lower system cost, higher efficiency, and reduced size and weight.

All conventional cooling methods rely on lowering the battery surface temperature, which increases internal temperature gradients, accelerates degradation, and ultimately caps the maximum heat removal rate once the allowable temperature difference is reached.

- True breakthrough performance requires lowering internal battery thermal resistance

There are only two physics-based ways to increase heat removal in a battery: lower the cell surface temperature or lower the battery’s internal thermal resistance.

Since surface temperature cannot be lowered further without harming battery life, reducing internal thermal resistance is the only viable path to transformative thermal performance. Once the maximum temperature difference is reached, all cooling methods become effectively the same.

- ParaThermic® High-Heat Transfer (HHT) batteries enable transformative thermal management

ParaThermic® HHT batteries introduce a mechanical, non-chemical innovation that lowers the internal thermal resistance of the cell. This enables dramatically higher heat flow without increasing degradation and removes the heat-transfer ceiling imposed by conventional designs.

The result is a path to the unprecedented EV performance metrics customers want, including faster charging, better cold-weather operation, improved safety, extended life, and higher energy efficiency.

Why electric vehicles (EVs) need battery thermal management

Battery thermal management refers to the methods used to keep lithium-ion batteries within their optimal operating temperature [3].

Effective thermal management is essential for maintaining battery performance, lifetime, and safety. In electric vehicles, the battery thermal management system works to keep cell temperatures within an operating window of roughly 15°C to 35°C.

If the battery is too cold, it will result in:

- Reduced vehicle power, leading to slower acceleration

- Reduced battery capacity, decreasing vehicle range

- Reduced fast-charging capability

If the battery is too hot, it will result in:

- Faster degradation, reducing the battery’s ability to stay charged

- Shortened overall battery life

- Reduced battery capacity, decreasing vehicle range

- Increased occupant safety risks due to higher thermal runaway likelihood

Robust battery thermal management is essential for modern EVs [6, 9-10].

How a Battery Thermal Management System Works

Battery thermal management systems work by adding to or removing heat from the battery at the right times to raise or lower the battery temperature. Adding heat to a battery raises its temperature (battery heating), removing heat from a battery lowers its temperature (battery cooling).

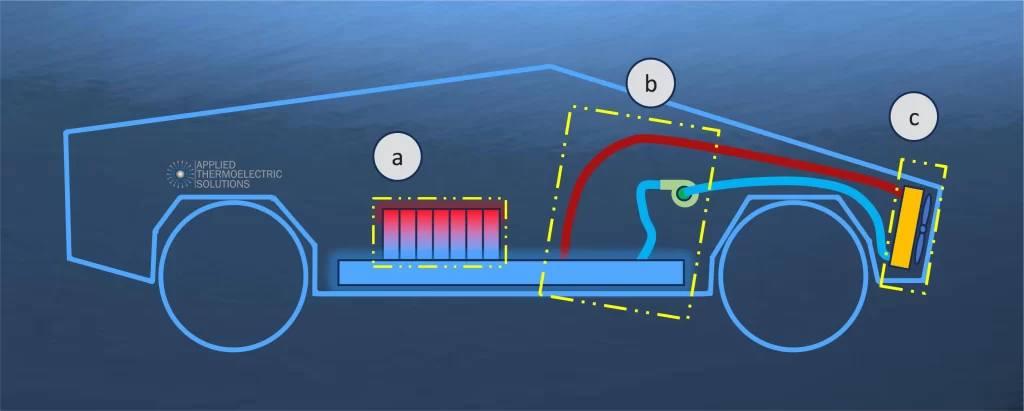

The image above shows a typical battery thermal management system (BTMS) and highlights its three main heat-transfer pathways: (a) conducting heat from the center of the battery to the cell surface, (b) transferring heat from the cell surface to the radiator using a cooling medium such as liquid coolant, refrigerant, or air, and (c) rejecting that heat from the radiator to the surrounding ambient air.

While in operation, batteries generate heat internally. The heat generated is proportional to vehicle acceleration rates or battery charging rates. If this heat generation rate exceeds the rate at which the thermal management system removes the heat, battery temperature rises.

EVs operate in a wide range of climates from very cold to very hot which means the thermal management system needs to be effective at adding or removing heat in a wide range of environmental scenarios.

In cold weather, heat may not be generated during vehicle operation fast enough to compensate for rate of heat leaving the battery to the cold ambient. In this case battery temperature will fall. Therefore, heat needs to be added to the battery by the thermal management system to bring the temperature to optimal.

In hot climates, heat generated internally in the battery will need to be removed in addition to heat entering the battery from the hot climate. This further increases amount of heat that must be removed by the battery thermal management system.

The thermal management system must be designed to add or remove the right amount of heat from the battery under a diverse range of vehicle operating and environmental conditions to maintain optimal battery temperature.

Battery Thermal Management Methods: Two Fundamental Approaches

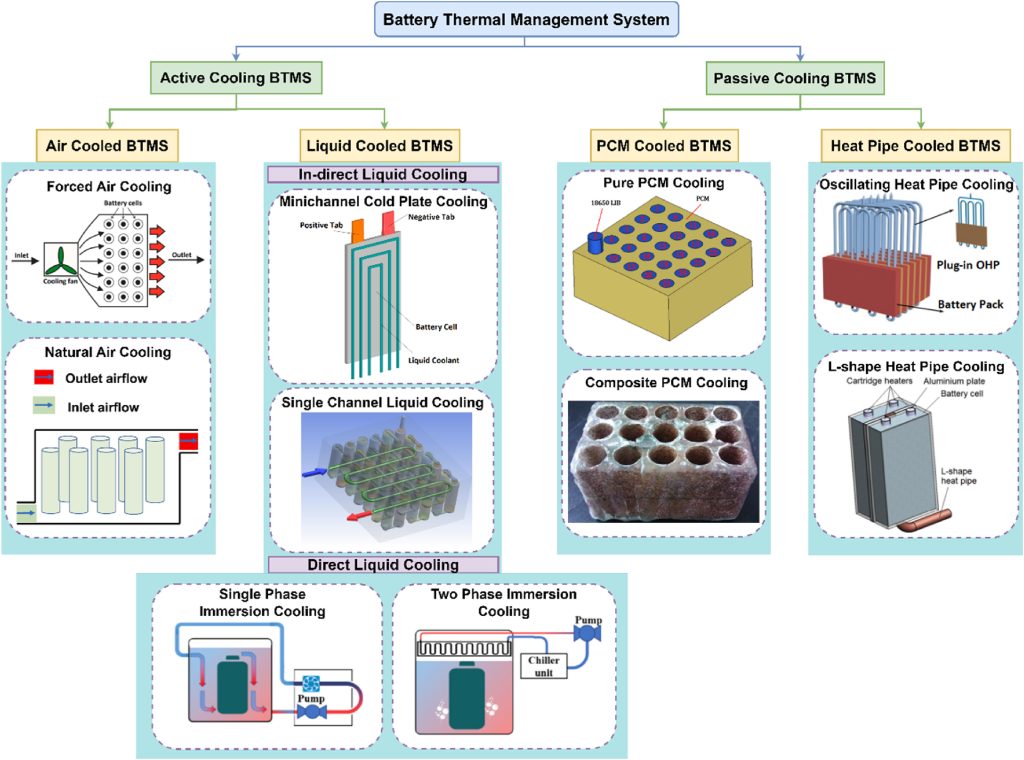

In a historical context, battery thermal management has primarily focused on selecting a cooling method, such as air, liquid, or refrigerant, and engineering a system capable of removing the necessary amount of heat from the battery.

However, as demands for fast charging, cost efficiency, safety, and performance have increased, these cooling methods have become more complex. Modern systems now include approaches such as:

- Phase change materials (PCMs)

- Pumped two-phase cooling systems

- Dielectric fluid immersion cooling

- Jet impingement cooling

These sophisticated methods aim to keep pace with the rising heat-removal requirements of today’s high-performance batteries.

Yet, despite these advances, cooling methods alone have proven insufficient to meet the thermal challenges posed by modern batteries.

To understand why, we must return to the fundamental principles of heat transfer. Heat can only move when a temperature gradient exists within an object, meaning the surface must be cooled to draw heat from the interior.

Batteries follow this same principle, but with an added complication. As heat generation within the battery increases, the temperature gradient required to remove that heat can accelerate battery degradation. Simply increasing the cooling intensity is no longer a viable solution.

This is where heat transfer physics comes into play.

Equation 1 shows that, from a heat transfer perspective, there are only two ways to increase the battery heat removal rate:

\dot{Q}_{\text{batt}} = \frac{\Delta T_{\text{batt}}}{R_{\text{th,batt}}} \tag{1}

Method 1: Increase the temperature difference ΔT across the battery by improving cooling methods.

Method 2: Reduce the battery’s internal thermal resistance Rth,batt, which allows heat to move efficiently with a lower ΔT.

Modern batteries have already reached or exceeded the safe ΔT limit. With increased demands such as faster charging, Method 2, reducing the battery’s thermal resistance, becomes the only viable option moving forward. (see The Limitations of Today’s Battery Thermal Management Systems below)

In short, Method 1 alone is no longer sufficient. Modern thermal management requires a combined approach, with Method 2 playing a critical role in protecting high-performance batteries.

Examples of Method 1 to Increase \dot{Q}_{\text{batt}}: Lowering Battery Surface Temperature (Increasing ΔT)

From the image above, thermal management systems regulate the temperature at the cell’s center T1, so the only way to increase ΔT is by lowering the surface temperature T2. Lowering T2 increases the heat removal rate while keeping the cell core at its target operating temperature.

There are three primary ways (1.1, 1.2, 1.3 below) to reduce the battery surface temperature T2 and thereby increase the temperature difference ΔT between the battery core and surface. Increasing this temperature difference improves the rate of heat removal from the battery.

This relationship can be expressed mathematically as:

T_2 = T_\text{ambient} + \dot{Q}_\text{batt} \left( \frac{1}{h_\text{batt} A_\text{batt}} + \frac{1}{U_\text{rad} A_\text{rad,fins}} \right) \tag{2}

Below we will talk about all three methods to lower surface temperature, 1.1, 1.2 and 1.3.

1.1 Enhance heat transfer at the battery surface \left( h_{\text{batt}} \right)

Heat transfer can be improved using progressively more effective higher heat transfer coefficient cooling methods, including:

- Natural convection [11]

- Forced air cooling [12]

- Pumped single-phase liquid cooling [4]

- Phase Change Materials (PCM) [13]

- Thermoelectric cooling (Peltier devices) [14]

- Vapor compression refrigeration (chillers) [15]

- Heat Pipes [26]

- Dielectric fluid immersion cooling [16]

- Pumped two-phase cooling [17]

- Jet impingement cooling [5]

While increasing the heat transfer coefficient and thus increasing ΔT is the most common approach to improving battery heat removal, it has a fundamental limit.

To keep battery degradation and safety risks low, it is recommended to cap the temperature difference across a cell at 3°C [20].

Although, in theory, higher ΔT would increase heat transfer according to the laws of physics, all systems that respect this 3°C ΔT limit end up delivering essentially the same maximum heat removal rate.

This illustrates why even the most advanced cooling technologies eventually hit a point of diminishing returns. The practical implications of this limitation are discussed in the “The Limitations of Today’s Battery Thermal Management Systems” section below.

Just as pushing more water through a narrow hose requires a larger pressure gradient, moving more heat out of a battery requires a larger temperature gradient. Modern cooling systems can create that temperature difference, but doing so accelerates battery degradation and increases safety risks.

If we want to move more water without increasing pressure, or more heat without increasing the temperature difference, we need to make the hose wider. In battery terms, that means lowering the internal thermal resistance so heat can flow more easily from the inside to the outside.

1.2 Increase the thermal contact area between the battery and the cooling system \left( A_{\text{batt}} \right)

The next method of lowering battery surface temperature to increase ΔT is to increase the surface area over which the cooling method acts.

A key example is dielectric fluid immersion, which surrounds the entire battery cell in a dielectric fluid.

While immersion cooling offers a relatively high heat transfer coefficient, its true advantage comes from the increased contact area with the battery.

This larger contact area lowers the average surface temperature and raises the average ΔT between the cell surface and core, significantly improving the battery’s heat transfer rate.

1.3 Increase radiator performance (Increase area or heat transfer coefficient) \left( U_{\text{rad}} A_{\text{rad,fins}} \right)

For systems that use a coolant loop and radiator (rather than direct air cooling), increasing radiator heat transfer area and / or improving its overall heat transfer coefficient increases the system’s ability to reject heat to the environment.

Better heat rejection lowers the coolant temperature, which in turn lowers the battery surface temperature and increases the heat transfer ΔT at the battery.

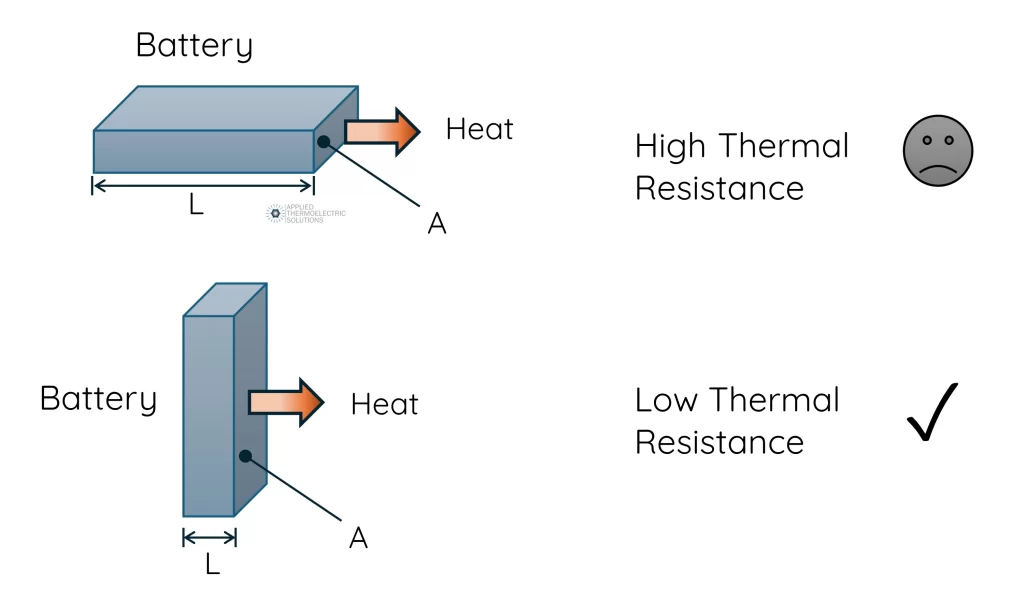

Example of Method 2 to Increase \dot{Q}_{\text{batt}} : Lowering the battery thermal resistance

The second method from Equation 1 is to reduce the battery’s thermal resistance. In this context, thermal resistance is analogous to electrical resistance: temperature difference (ΔT) is analogous to voltage difference, and heat flow (Q̇) is analogous to electrical current.

To understand thermal resistance, consider the analogy to electrical resistance. If electrical resistance decreases, more current flows for the same voltage difference.

Likewise, decreasing thermal resistance allows more heat to flow through the battery for a smaller temperature gradient. This is exactly what battery thermal management requires. In batteries, we want higher heat flow with a smaller ΔT.

Now consider Equation (3) below, which describes the thermal resistance of a rectangular body such as a battery cell.

R_{\text{th,batt}} = \frac{L}{k A} \qquad (3)

- L = heat-flow distance

- k = thermal conductivity in the direction of heat flow

- A = area normal to the heat-flow direction

From this relationship, there are three fundamental ways to reduce thermal resistance (2.1, 2.2, and 2.3):

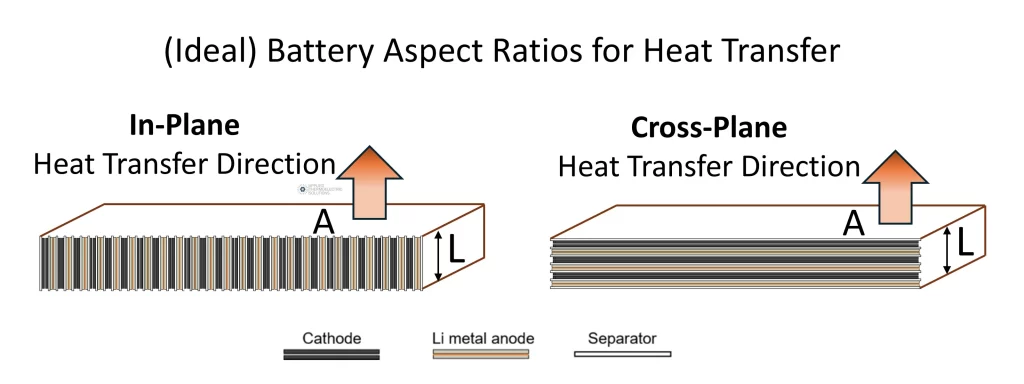

2.1 Decrease the heat-flow path length (L)

Shorter thermal paths allow heat to leave the battery more easily.

Example:

Designing battery cells to be very thin in the heat-transfer direction.

2.2 Increase the heat-transfer area (A)

Increasing the available area for heat flow reduces resistance.

Example:

Using pouch cells with a large area normal to the heat-transfer direction.

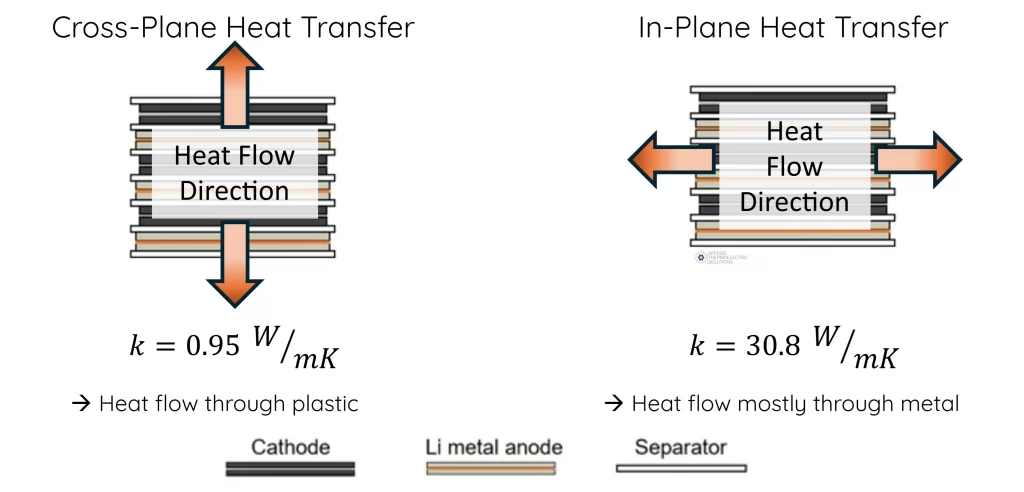

2.3 Increase thermal conductivity (k)

Increasing k in the direction of heat flow along the chosen path reduces R_{\text{th}} .

Example:

Using the high-thermal conductivity in-plane heat path through the battery for heat transfer.

The Limitations of Today’s Battery Thermal Management Systems

Today’s battery thermal management strategies rely almost entirely on Method 1 to increase battery heat removal as discussed above, which lowers the battery surface temperature to increase ΔT. This approach inherently creates larger internal temperature gradients, which accelerate battery degradation and reduce cell lifespan [18-19, 24].

To limit this damage, the United States Advanced Battery Consortium (USABC) recommends keeping the temperature difference across a cell below 3 °C [20]. By Equation 1, this constraint also limits the maximum heat removal rate, no matter how advanced the external cooling system may be.

Even with liquid cooling, refrigerant-based cooling, or dielectric immersion systems, heat can only escape the cell as fast as it travels through the cell’s internal thermal pathways. This fundamental bottleneck means improvements to external cooling alone cannot enable substantially faster charging or significantly longer battery life.

In practice, many designs exceed the 3 °C guideline [21-22] to achieve required charging and power levels. This sacrifices durability and thermal safety in exchange for performance and highlights that today’s ΔT-driven approach is approaching or has already reached its physical and practical limits.

Furthermore, this challenge is expected to intensify in the future. Today’s EV chargers are typically limited to 250 kW, but 1000 kW chargers are on the horizon. These ultra-fast chargers often supply chilled water to the battery thermal management system, attempting to increase ΔT in cells already near or past their ΔT limit.

If charging power quadruples to 1000 kW, the electrical current also quadruples, which, by I²R heating, can increase internal heat generation by up to 16×. According to Equation 1, accommodating this level of heat would require a ΔT far exceeding the 3 °C limit recommended by USABC, which is clearly infeasible.

By deduction from Equation 1, the only remaining path forward is to reduce the internal thermal resistance of the battery cell itself. However, even with existing attempts such as thinner pouch cells, edge cooling, or tab cooling, the reductions in thermal resistance have been modest.

These approaches have not delivered the step-change required for transformative improvements in fast charging, battery longevity, or battery safety.

What’s Needed: Next-Generation, Transformative Battery Thermal Management

Transformative battery thermal management refers to systems that meet the requirements necessary to take battery and EV performance [1] to the next level. To overcome the limitations of today’s ΔT-driven cooling strategies, a truly transformative battery thermal management system must deliver:

- Substantially increased heat removal rates

To enable faster charging and higher-power driving, the battery thermal management system must be able to remove heat much faster than today’s systems allow without going over the ΔT limit [10, 23]. - Improved battery temperature uniformity

The temperature difference between the hottest and coldest points in the cell must be 3 °C ΔT or less, with lower being even better to prevent accelerated aging and protect safety [10, 23]. - Much faster thermal response

When heating or cooling is applied, the battery must change temperature quickly, not slowly as in current systems where internal thermal resistance limits responsiveness [10, 3]. - Lower overall system cost

Next-generation thermal management must reduce cost through simpler hardware, fewer components, or decreased material requirements [10, 3]. - Higher BTMS efficiency

The system must provide more cooling power while using less electrical power, improving EV range and reducing parasitic load [10, 3]. - Size and weight reduction

Electric vehicle batteries need size and weight reduction to improve efficiency, increase driving range, and make vehicles more practical and cost-effective [10, 3].

With these improvements, batteries could achieve the performance level required.

Our solution: Introducing the ParaThermic® High-Heat-Transfer HHT Battery

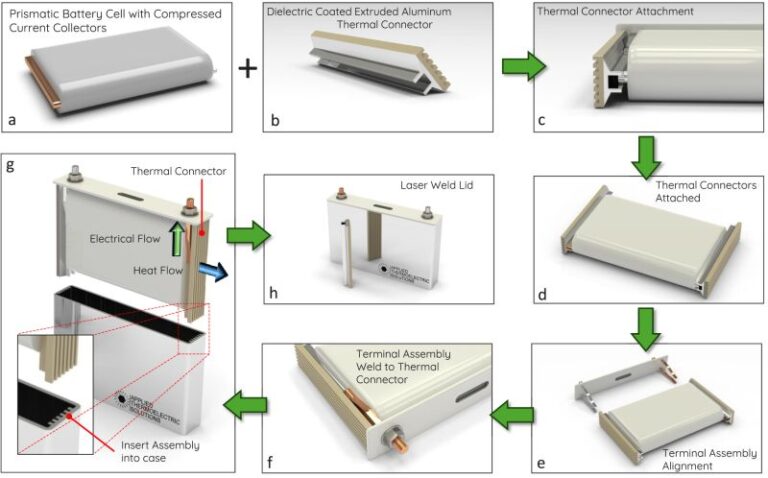

Patented High Heat Transfer (HHT) ParaThermic® batteries are structural, non-chemical battery design for EVs and other applications that integrate advanced thermal pathways directly into the cell architecture. By improving internal heat transfer rather than altering chemistry, we remove the thermal bottlenecks that traditionally restrict fast charging, cold-weather performance, cycle life, and safety.

By directly reducing the battery’s internal thermal resistance, the fundamental barrier described in Equation 1, ParaThermic® HHT batteries enable dramatically faster heat removal. This enables:

- Extreme Fast Charging (XFC) thermal capabilities

- Strong cold-weather performance with minimal power or range loss

- Substantially longer battery life, at least three times longer

- Improved safety and reduced thermal-runaway risk

- Reduced battery thermal management system (BTMS) power consumption

- Thermal support for higher energy density battery chemistry

- Lower costs

This is the first structural battery innovation designed specifically to achieve transformative battery thermal management from the inside out.

How ParaThermic® High-Heat Transfer HHT Batteries Work

The ParaThermic® High Heat Transfer Battery is based on the core principle demonstrated in Equation 1. Increasing heat removal requires reducing internal thermal resistance. Once external cooling methods reach their ΔT limit, this is the only path to transformative thermal performance.

Key Engineering Innovations Behind ParaThermic® High-Heat Transfer HHT Batteries

HHT batteries achieve transformative battery thermal management through four key engineering innovations.

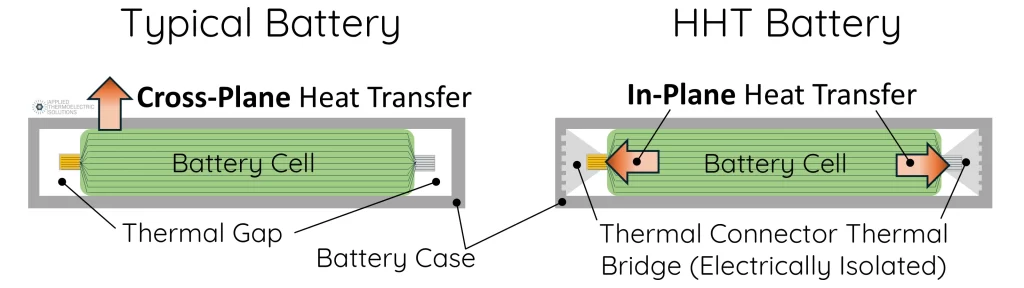

- In-plane heat transfer

Battery construction consists of layers of anode, cathode, and separator, which have highly anisotropic thermal properties. Heat travels roughly 32 times faster within the plane of the layers than across them.

Conventional battery designs force heat to travel across the layers, which is the slower direction. HHT batteries redirect heat flow into the fast in-plane direction, substantially increasing the effective thermal conductivity of the cell.

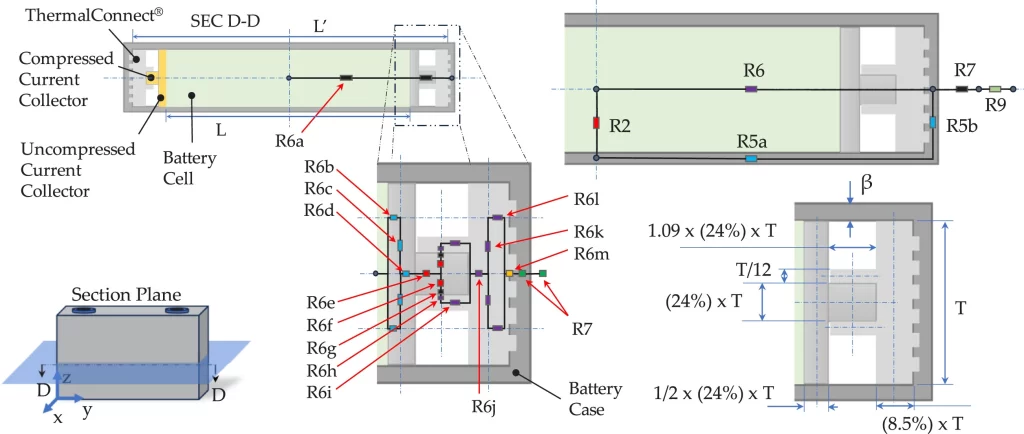

- Optimized battery aspect ratio for in-plane heat transfer

Equation 3 shows that internal thermal resistance depends strongly on battery aspect ratio.

Unlike traditional batteries that are optimized for the lower-thermal-conductivity cross-plane heat transfer, HHT batteries optimize the aspect ratio specifically for in-plane heat flow.

This shortens heat-travel distances and increases the area available for heat flow, while leveraging the much higher in-plane thermal conductivity.

The combination significantly improves the battery’s ability to move heat out of the cell interior and provides performance never seen in traditional batteries.

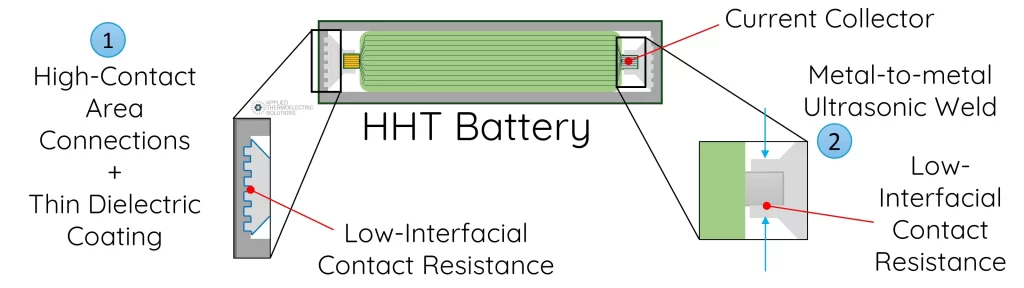

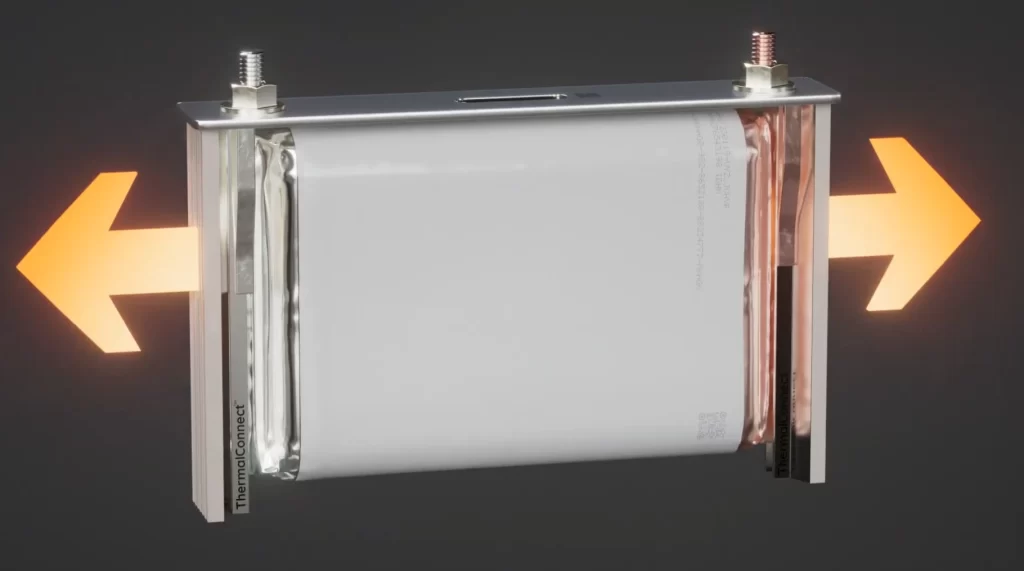

- Electrically isolated thermal bridging using ThermalConnect®

To make in-plane heat transfer possible, the electrically energized in-plane heat-flow direction must be thermally bridged between the battery cell and the battery case using electrically isolated, thermally conductive ThermalConnect® thermal bridges.

This enables heat to escape along the battery’s highest-conductivity pathways without creating electrical short paths, unlocking the full thermal performance potential of the HHT architecture.

- Low thermal interface resistances through precision bonding

For efficient heat transfer, we ensure that interfacial thermal contact resistance is kept extremely low by using processes such as ultrasonic welding to form high-conductivity bonded metal interfaces, applying only thin functional coatings, and maximizing contact area.

Together, these measures allow heat to flow unobstructed from the battery into the external cooling system.

ParaThermic® High-Heat Transfer HHT batteries are optimally configured for side cooling rather than traditional base cooling. Some modern EV platforms have already adopted side-mounted cooling plates, although they still remove heat through the cross-plane direction rather than the in-plane direction. This shift demonstrates that vehicle-level layouts compatible with side cooling already exist, providing a natural integration pathway for HHT batteries without requiring major architectural changes.

Performance Advantages of ParaThermic® HHT Batteries

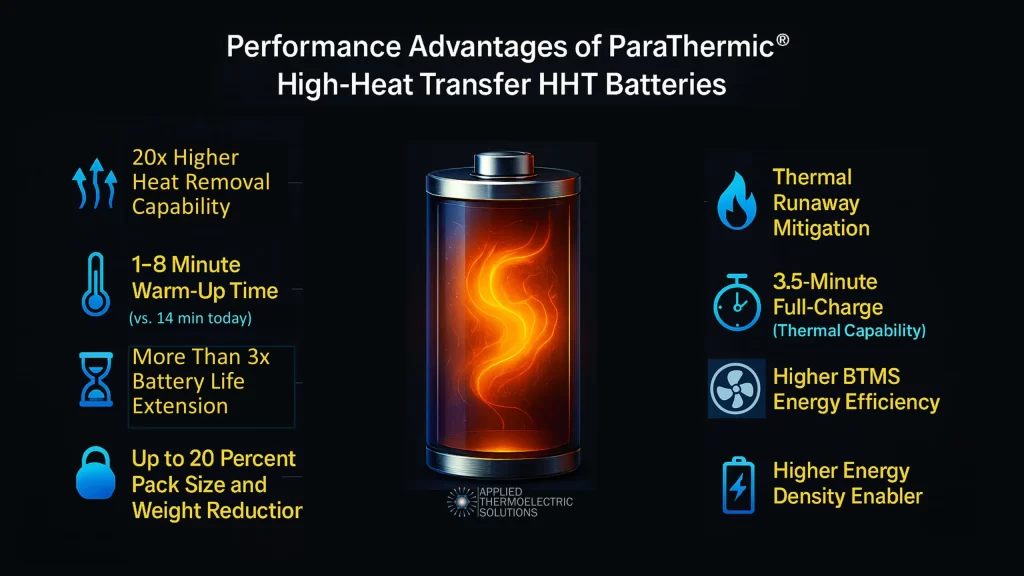

20× Higher Heat-Removal Capability (or more)

Modeling shows a 1.3–2.6× increase in maximum heat-removal rate using current production aspect ratios, and up to a 20× improvement with optimized aspect ratio with trends projected even higher. This is a key enabler for advanced EV battery thermal management and fast-charging performance [10]

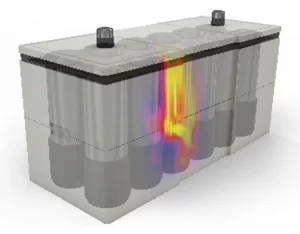

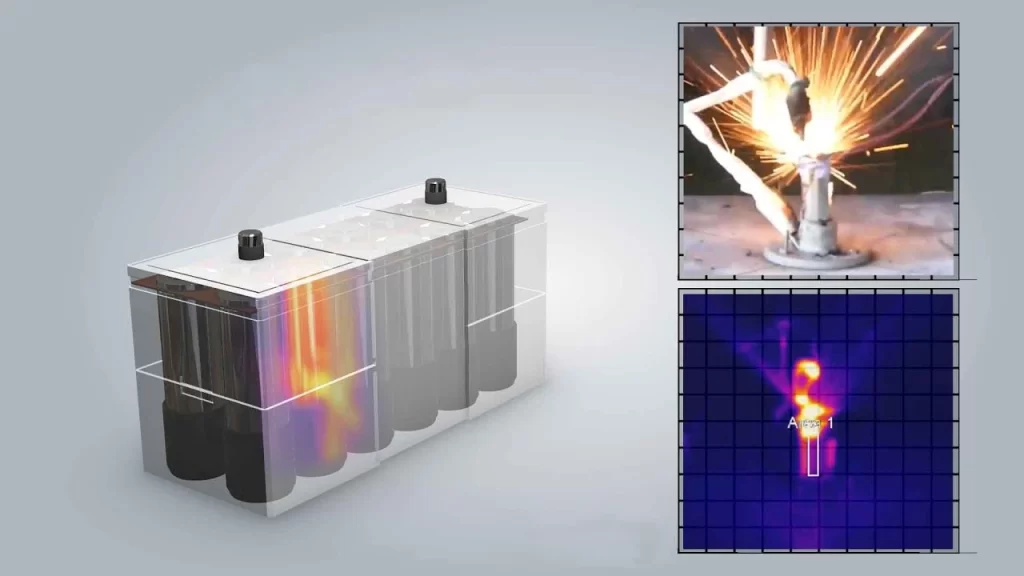

Thermal Runaway Mitigation

Batteries are susceptible to thermal runaway. Thermal runaway occurs when a battery generates more heat than it can dissipate, causing cell temperature to rise rapidly. Once the battery reaches a critical range of roughly 120 to 150 degrees Celsius, a self-accelerating exothermic reaction can begin. Our modeling shows that with HHT battery architecture, heat can be removed from the cell faster than it is generated during the early onset stage. Depending on the battery’s aspect ratio, this capability can significantly delay thermal runaway or prevent it from developing. Typical batteries cannot remove heat fast enough to offer this level of thermal stability. [10]

3.5-Minute Full-charge Thermal Equivalent (17C-rate)

Thermal modeling indicates that HHT batteries could support the heat-removal rates required for a 3.5-minute full charge, which corresponds to a 17C charge rate. This level of heat-transfer capability is essential for true extreme fast charging (XFC). [10]

1–8 Minute Warm-up Time (vs. 14 minutes today)

EVs lose power, range, and charging capability in cold weather. HHT architecture increases heat flow into the battery by 1.8× to 14×, depending on cell aspect ratio and reducing warm-up times to as little as 1–8 minutes per our internal modeling. This prevents drivers from experiencing cold-weather performance loss.

More than 3× Battery-Life Extension

Temperature effects have been shown to have a profound impact on battery life. Specifically, reducing the maximum temperature of the cell, lowering the time spent at elevated temperatures, reducing temperature gradients between layers, and reducing temperature gradients within layers all contribute to improved longevity.

Research has shown that eliminating inter-layer temperature gradients alone can improve battery life by up to three times [19].

HHT batteries improve temperature conditions across all of these dimensions. While the three-times improvement is well established in the research literature, HHT’s combined gains across all temperature factors suggest that an even greater improvement in cycle life is achievable.

Up to 20% Pack Size and Weight Reduction

EV battery packs are typically oversized by 10–20% to compensate degradation and ensure a minimum capacity at the end of their life.

Because HHT batteries degrade more slowly, much of this oversizing may no longer be required [4]. Reducing a 100-kWh pack by 10–20 kWh could save up to $2,000 at $100/kWh while improving vehicle range and reducing weight.

Higher BTMS Energy Efficiency

By lowering the battery’s internal thermal resistance, HHT reduces the temperature difference required to move heat out of the cell. As a result, the cell surface does not need to be as cold to achieve the same heat transfer rate.

Cooling systems such as vapor-compression units operate more efficiently when the temperature difference between the object being cooled and the ambient environment is smaller.

For non–vapor compression liquid-cooled systems, the lower internal battery ΔT allows the cell surface temperature to be much closer to the interior, which in turn allows a larger ΔT between the radiator surface and ambient air, increasing heat-transfer efficiency.

For the same heat-rejection requirement, this can reduce the size and power of fans and may even allow the radiator to be downsized, lowering aerodynamic drag.

The result is a BTMS that consumes less power for the same cooling load and contributes to increased EV driving range [10].

Higher Energy Density Potential

ThermalConnect® thermal bridges occupy space that is unused in conventional battery designs, preserving energy density relative to existing cells.

Next-generation ThermalConnect® geometries have the potential to optimize this space even further, allowing HHT cells to fit more active material within the same package volume and thereby increase energy density.

Furthermore, higher–energy density chemistries typically generate more heat, and HHT’s enhanced heat-transfer capability has the potential to enable those chemistries [10].

Lower Cost through the Option of Air Cooling

Because HHT dramatically increases heat-removal capability, it may enable 15-minute fast charging using low-cost air cooling.

Air-cooled thermal systems are significantly less expensive than liquid, refrigerant, or immersion-cooling systems [10].

Simpler, Lower-Cost Battery Packs

With HHT’s ability to support thicker cells, fewer cells may be required per pack. This reduces components such as bus bars, connectors, welds, wiring, and structural hardware.

A pack with fewer parts lowers material cost, labor, assembly time, and the complexity of both the BMS and BTMS [10].

Modeling Scope

The results presented here were obtained using a specific range of battery aspect ratios. While the modeling did not cover all possible configurations, the trends are clear: as aspect ratios are further optimized, we expect additional improvements in heat removal, charging speed, cold-weather performance, and overall thermal uniformity.

These directional trends indicate that the benefits of HHT could continue to grow beyond the values reported in this study [10].

Promising Applications of HHT Batteries

High-Performance Electric Vehicles (EVs)

HHT batteries enable faster charging, improved safety, and longer battery life by dramatically reducing thermal hotspots.

High-performance EVs, commercial fleets, and long-range vehicles benefit the most because thermal limits often restrict charging speed and power output.

Grid-Scale and Renewable Energy Storage

In energy storage systems, HHT batteries allow higher charge and discharge rates with reduced degradation.

This improves the efficiency and longevity of grid-tied and renewable energy storage solutions.

Consumer Electronics

Fully scalable HHT technology can be applied to smartphones, tablets, gaming laptops, drones, and AR/VR devices.

Benefits include ultra-fast charging, better thermal safety, higher sustained performance, and longer battery life, all critical in heat-constrained, compact devices.

Aerospace and Industrial Applications

Drones, electric aircraft, and high-power industrial tools can operate more safely and efficiently.

HHT enables higher energy density and thermal stability without chemical modifications, which is important for weight-sensitive or high-stress applications.

Future Work and Collaboration Opportunities

We plan to begin building prototypes to validate the HHT battery technology and demonstrate its performance under real-world conditions, minimizing technical risk while proving high-value benefits.

At the same time, we are engaging with original equipment manufacturers to gather early input, guide development, and explore co-funding opportunities. Working closely with OEM partners will also allow us to assess production costs and identify potential manufacturing constraints.

Following successful testing and feedback, we will explore licensing and commercialization opportunities to bring this transformative, low-risk, high-reward technology to market.

Industry Presentations and Technical Engagement

This HHT battery research has been shared at leading battery thermal management and EV engineering conferences, such as:

• The Battery Show North America

• The Thermal Management Systems Symposium

• SEMI-THERM

• Electrochemical Society (ECS) Meetings

These presentations drew strong engagement from automotive OEMs, EV thermal management engineers, and national laboratories. Audience discussions focused on the status of the development, how the architecture applies to different cell formats, and how HHT batteries could be integrated into next generation EV platforms. This level of interest reflects the growing recognition that new battery thermal management approaches are needed to support future EV performance requirements.

Conclusion

Battery thermal management is a critical factor in electric vehicle performance, safety, and longevity.

Traditional approaches have reached their limits, making next-generation solutions essential for faster charging, improved cold-weather performance, higher energy density, and extended battery life.

This article provides engineers, scientists, and industry innovators with expert guidance on designing transformative battery thermal management systems to achieve next-level electric vehicle performance.

Join the Battery Thermal Management Engineering Community

Join the Battery Thermal Management Community

If you found this article useful, you may want to stay connected with others working on fast charging, battery safety, EV thermal systems, and next-generation cell design.

Join our Battery Thermal Management Group on LinkedIn to participate in technical discussions, share research, and stay informed on evolving engineering practices.

👉 Join the LinkedIn Group

Get Updates and Technical Insights

If you’d like early access to technical articles, modeling insights, prototype development updates, and research on ParaThermic® HHT batteries:

👉 Sign up for the email list

Download the ParaThermic HHT Battery Overview

For a concise engineering reference, download the one-page summary of HHT battery architecture. It highlights the fundamental thermal design principles, heat-transfer improvements, and performance benefits discussed in this article.

Frequently Asked Questions

What is EV battery cooling and why is it important for EVs?

EV battery cooling refers to managing and controlling the temperature of lithium-ion cells in electric vehicles. An effective battery thermal management system maintains optimal cell temperature to improve EV performance, safety, battery lifespan, and fast charging capability.

As customers expect electric vehicles to match or exceed the performance of gas-powered vehicles, thermal management becomes one of the most important factors influencing real-world driving performance, reliability, and charging consistency.

What limits current EV battery thermal management systems?

Current EV battery thermal management systems are limited by the internal thermal resistance of the lithium-ion battery cell. This internal resistance controls how much temperature difference is required to drive heat from the cell core to the surface, which ultimately caps the cooling capability of any external battery cooling method. Most modern EV batteries already operate past their maximum allowable temperature delta, so additional heat extraction would accelerate degradation or reduce battery life.

Lowering internal thermal resistance enables higher heat transfer rates at the same temperature gradient or allows the same heat removal with a much smaller temperature gradient, which is essential for next-generation battery thermal management and future EV fast charging performance.

These limits apply only to today’s internal heat-transfer pathways. When internal thermal resistance is reduced, the allowable heat flow increases without requiring larger internal temperature differences, shifting the fundamental limit.

How can next-generation battery thermal management improve EV performance?

Combining low thermal resistance batteries with today’s advanced cooling technologies significantly increases the total heat removal capability of an EV battery system. This enables faster charging, improves cold-weather performance, supports higher energy density chemistries, delays or mitigates thermal runaway, and extends battery life.

When the cooling system and the internal battery architecture are aligned, overall EV performance can improve across nearly every operating condition.

What are common methods used in EV battery cooling?

Methods used in EV battery cooling include air cooling, liquid cooling, phase-change materials, immersion cooling, and thermoelectric cooling. Each method has trade-offs in cost, complexity, reliability, and thermal performance depending on the battery design, operating conditions, and vehicle requirements.

Selecting the optimal cooling method depends on the battery’s internal thermal resistance and the vehicle’s fast-charging, safety, and performance goals.

How do battery thermal management systems affect battery lifespan?

Maintaining lithium-ion cells within their optimal temperature range is essential for maximizing battery lifespan. Because cell temperature varies during driving and fast charging, the battery thermal management system must keep the cells at optimal temperature as consistently as possible while preventing excessive temperature rise during high heat generation events. However, battery life is influenced not only by average temperature but also by internal thermal gradients created by the cooling method.

Cooling the battery from the in-plane direction can significantly reduce layer-to-layer temperature gradients, improving thermal uniformity across the stack. A second type of gradient occurs within each individual layer, and minimizing this requires a low thermal resistance heat path inside the battery. This low-resistance path allows high heat flow without creating harmful internal temperature variations that accelerate cell aging.

Can new battery thermal management designs reduce EV charging times?

Yes. New battery thermal management designs can reduce EV charging times by allowing the cooling system to remove heat at the same rate the battery generates it during fast charging. When heat removal matches heat generation, battery temperature stays within safe limits and charging power does not need to be reduced.

However, internal temperature gradients created by the cooling method must also remain below degradation thresholds. A low thermal resistance heat path ensures that the temperature delta required for the needed heat removal does not create harmful gradients inside the cell. This enables higher charging power without triggering thermal limits that force the battery management system to slow the charge.

How can EV battery cold-weather performance be improved?

Cold-weather performance improves when a battery can absorb heat quickly without creating large temperature gradients. By lowering a battery’s internal thermal resistance, heat can move into the cell much faster without exceeding temperature limits on the heater side.

This allows the battery to warm up rapidly. With HHT batteries, the battery has the potential to reach optimal temperature much sooner, enabling preheating before the customer drives away and reducing or eliminating the cold-weather power loss and range reduction common in today’s EVs.

What is thermal energy flow in batteries?

Thermal energy flow refers to the rate at which heat moves into or out of a battery. This occurs during heating, cooling, and temperature regulation by the battery thermal management system. Higher thermal energy flow allows the battery to warm up faster in cold conditions, cool down faster during fast charging or high-power operation, and maintain stable temperatures that protect performance and lifespan.

How can engineers and researchers stay ahead in battery thermal management design?

Following advanced research, forward-looking engineering frameworks, and emerging battery architectures helps engineers stay ahead. Engaging with OEMs, research institutions, and suppliers enables the adoption of next-generation battery thermal management systems strategies and technology solutions that address limitations of current EV battery designs.

Can cooling system technology keep up with next-generation batteries?

Battery temperature delta is a critical indicator of whether a battery is reaching its thermal limits. A temperature difference of about 3 degrees Celsius or less across the cell is generally recommended to avoid accelerated degradation and safety risks. Many current EV batteries are already operating close to or exceeding this limit during heavy load or fast charging, which shows that today’s cooling technologies are essentially maxed out.

Relying on further increases in temperature difference to achieve the heat-transfer levels required for next-generation performance is not realistic. Supporting future EV performance will require batteries with fundamentally lower internal thermal resistance so that high heat flow can occur without creating excessive temperature gradients.

Hasn’t in-plane heat transfer been around for a while? Is HHT just another form of edge cooling or tab cooling?

In-plane heat transfer itself is not new. Prior work on tab cooling and today’s commercial edge-cooled cells also use in-plane heat flow, but they apply it to otherwise conventional batteries. These approaches simply cool a normal cell from the edge or from the tabs.

ParaThermic® HHT batteries are not that.

Yes, they use in-plane heat transfer, but it is only one element of a fully reengineered internal architecture. The limited performance gains from commercial edge-cooled batteries show that in-plane heat transfer by itself is not enough to unlock transformative vehicle-level improvements.

HHT is not a conventional cell with in-plane cooling added.

It is a new battery architecture whose entire design is built around eliminating internal thermal bottlenecks, far beyond what edge or tab cooling can achieve.

With major heat-removal improvements from HHT batteries, will the cooling system and radiator need to be larger?

Not necessarily. The highest heat generation in EV batteries occurs during extreme fast charging, which is moving toward megawatt-level charging power. One megawatt of charge power can produce roughly 100,000 watts of heat inside the battery pack.

It is impractical to size an onboard radiator or cooling system to reject that much heat. For this reason, megawatt charging systems supply chilled coolant from the charging station directly to the vehicle’s battery thermal management system. As a result, upsizing the onboard radiator or battery thermal management system is not required, even when HHT batteries dramatically increase heat-removal capability.

However, while chilled coolant solves the problem of needing an impractically large onboard cooling system, it creates another challenge. Chilled coolant further increases the temperature delta imposed on the battery. Current batteries are already operating near or past their maximum allowable temperature delta, so increasing it further can create safety concerns or, at best, accelerate degradation.

This is where HHT batteries become essential. Their low internal thermal resistance allows high heat flow without requiring large internal temperature gradients, enabling the battery to handle extreme fast charging without exceeding temperature delta limits.

If ParaThermic® HHT batteries cool from the side, how do they integrate with existing base-cooled systems?

HHT batteries have been modeled primarily for side cooling, since this orientation provides the shortest thermal path and the best performance for prismatic cells. However, it is plausible that HHT batteries would still offer meaningful thermal advantages under base-cooled configurations. One integration option is to rotate the prismatic HHT cell so the ThermalConnect® interface aligns with existing base-cooling plates.

It is also worth noting that some advanced EV battery thermal management systems are already moving away from base cooling and transitioning toward side cooling even with conventional cells. This means the thermal integration approach that best suits HHT batteries is already aligned with emerging industry architectures, making future adoption more straightforward.

Does ParaThermic® High-Heat Transfer battery design work for other cell formats?

Yes. ParaThermic® High-Heat Transfer (HHT) battery design can be applied to pouch, prismatic, and cylindrical cell formats. Our published materials focus primarily on prismatic cells because they are among the most difficult formats to thermally manage and represent a major share of the EV battery market. However, the underlying thermal principles and low thermal resistance architecture apply across all three cell types.

Can HHT battery technology be scaled?

Yes. HHT battery technology is inherently scalable because its thermal architecture is independent of chemistry and cell size. It can be applied to systems ranging from milliwatt-hour consumer devices to megawatt-hour energy storage systems. The same low-thermal-resistance design principles can be used in consumer electronics, electric vehicles, industrial equipment, and grid-scale storage, making HHT a broadly adaptable platform.

How can thermal runaway be mitigated with HHT technology?

Our modeling shows that under battery abuse conditions, the HHT architecture can remove heat at a rate that exceeds the heat generation rate during the onset stage of thermal runaway. Depending on the cell’s aspect ratio and configuration, this capability can delay thermal runaway or potentially prevent it entirely by suppressing the early-stage conditions required for runaway propagation.

Why are these called High-Heat Transfer batteries?

High-Heat Transfer batteries received their name because modeling shows up to 20 times greater heat-transfer capability compared to conventional cells. However, they could just as accurately be called low internal temperature difference batteries, because they can be used in two ways: either to achieve ultra-high heat transfer while staying within recommended temperature difference limits, or to deliver standard heat-transfer performance while operating at very low temperature difference.

Operating at lower temperature difference significantly reduces battery degradation, improving lifespan, reliability, and overall EV performance.

What is the status of the ParaThermic® HHT battery development?

We have completed the construction of ThermalConnect® prototype components, and we are now preparing to build and test full ParaThermic® HHT battery prototypes. These upcoming prototypes will be used to validate thermal performance, scalability, safety, and manufacturing feasibility.

How can an OEM get involved with ParaThermic® HHT batteries?

OEMs can get involved by contacting us through our website’s contact form and indicating the type of collaboration they are interested in. We welcome early partnerships related to prototype battery builds, bench-top evaluations, vehicle-level integration studies, joint research programs, and future commercialization or licensing opportunities.

How much do HHT batteries cost?

Costs depend on battery format, size, and production volume. However, we expect the additional cost of the HHT architecture to be offset by the value it creates across the full battery and vehicle system. Reduced degradation can allow 10 to 20 percent pack downsizing, which lowers total pack cost by a similar amount.

Additional value comes from improved reduced thermal runaway risk, faster charging capability, reduced cold-weather power and range losses, longer battery life, higher thermal management energy efficiency (range gain), and simpler, lower-cost pack designs. When these factors are combined, the net cost of adopting HHT technology can be significantly lower than the initial added cell cost.

Why does your publication include “A new era in battery thermal management”?

We included this phrase because current battery thermal management methods have reached or are rapidly approaching their physical and practical limits. While existing cooling technologies have enabled EVs to achieve today’s performance levels, the plateau in external cooling capability and the delta-T limits of current battery designs signal the end of that era.

ParaThermic® HHT battery architecture introduces a fundamentally different approach that reduces internal thermal resistance and unlocks new performance levels that conventional designs cannot reach. This shift represents a genuine new era in battery thermal management.

Piggott, A. J., Allen, J. S., & Pesaran, A. A. (2025). High-heat transfer lithium-ion batteries: A new era in battery thermal management. Applied Thermal Engineering, 272, 126347. https://doi.org/10.1016/j.applthermaleng.2025.126347

Abstract: Despite advances in lithium-ion battery technology, critical challenges remain that must be addressed to accelerate electric vehicle (EV) adoption and global energy transformation. Significantly improved battery thermal management (BTM) is key to overcoming these challenges. BTM approaches focus on increasing heat transfer coefficients via air, liquid, or refrigerant cooling, but less attention is given to reducing the battery’s thermal resistance, a major bottleneck for heat transfer. This work introduces a novel approach to reduce battery thermal resistance by integrating in-plane heat transfer with optimized cell geometry, minimized thermal resistances, and reduced interfacial resistances, representing a departure from previous methods. The standard prismatic can cell incorporating this technology is referred to as the high heat transfer (HHT) battery. An equivalent resistance battery thermal model is developed for speed and accuracy, validated against experimental data in the literature, demonstrating strong correlation and ensuring reliable predictions for real-world performance. Thermal performance metrics of the conventional and HHT batteries are compared using a parametric study with air, liquid, and refrigerant boundary conditions across a range of aspect ratios. The HHT battery shows a heat removal rate up to 20 times higher than a conventional battery. These findings suggest that HHT technology could be transformative for EV battery performance, enabling fast charging, mitigating thermal runaway, extending battery life, reducing cold-weather power loss, increasing reliability, lowering costs, and enabling higher energy density, all critical for EV adoption and energy transformation. Future work will focus on prototyping and real-world testing to refine these findings for commercial-scale applications.

Keywords: High heat transfer (HHT) batteries; Battery thermal management (BTM); ParaThermic® battery; ThermalConnect®; Extreme fast charging (XFC); Battery safety; Battery cooling

- ARPA-E, Electric vehicles for American low-carbon living, 2022. Available:

http://arpa-e.energy.gov/technologies/programs/evs4all - Liu, G. Zhang, C.-Y. Wang, Challenges and innovations of lithium-ion battery thermal management under extreme conditions: A review, ASME J. Heat Mass Transf. 145 (8) (2023) 080801. Available:

https://doi.org/10.1115/1.4056823 - Ortiz, P. Arévalo, D. Peña, F. Jurado, Recent advances in thermal management strategies for lithium-ion batteries: A comprehensive review, Batteries 10 (3) (2024) 83. Available:

https://doi.org/10.3390/batteries10030083 - P. Rugh, A. Pesaran, K. Smith, Electric Vehicle Battery Thermal Issues and Thermal Management Techniques, NREL/PR-5400-52818, Scottsdale Arizona, 2011. Available:

https://www.nrel.gov/docs/fy13osti/52818.pdf - Keyser, Thermal Implications for Extreme Fast Charge, Vehicle Technologies Office (VTO) Annual Merit Review and Peer Report Number: NREL/PR-5400-68339, National Renewable Energy Laboratory, Washington, D.C., 2017. Available:

https://www.nrel.gov/docs/fy17osti/68339.pdf - Smith, E. Wood, J. Neubauer, J. Myungsoo, P. Ahmad, Models for battery reliability and lifetime, in: Battery Congress 2013, Ann Arbor, Michigan, 2013. Available:

https://www.nrel.gov/docs/fy14osti/57746.pdf - Hou, L. Lu, L. Wang, A. Ohma, D. Ren, X. Feng, Y. Li, Y. Li, I. Ootani, X. Han, W. Ren, X. He, Y. Nitta, M. Ouyang, Thermal runaway of Lithium-ion batteries employing LiN(SO2F)2-based concentrated electrolytes, Nat. Commun. 11 (1) (2020) 5100.

https://doi.org/10.1038/s41467-020-18868-w - Li, Y. Xue, X. Feng, J. Liu, F. Zhang, S. Rao, T. Zhang, Z. Gao, Z. Du, C. Ni, J. Shi, H. Wang, C. Rong, D. Wang, Enhancing understanding of particle emissions from lithium-ion traction batteries during thermal runaway, ETransportation 22 (2024) 100354.

https://doi.org/10.1016/j.etran.2024.100354 - Wang, Y. Zhang, W. Li, Z. Gao, B. Zhang, M. Ouyang, Experimental study on the cell-jet temperatures of abused prismatic Ni-rich automotive batteries under medium and high states of charge, Appl. Therm. Eng. 202 (2022) 117859.

https://doi.org/10.1016/j.applthermaleng.2021.117859 - Piggott, A. J., Allen, J. S., & Pesaran, A. A., High-heat transfer lithium-ion batteries: A new era in battery thermal management, Applied Thermal Engineering, 272, 126347, 2025.

https://doi.org/10.1016/j.applthermaleng.2025.126347 - Kalkan, A. Celen, K. Bakirci, Experimental and numerical investigation of the LiFePO4 battery cooling by natural convection, J. Energy Storage 40 (2021) 102796.

https://doi.org/10.1016/j.est.2021.102796 - Wang, K.J. Tseng, J. Zhao, Z. Wei, Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air cooling strategies, Appl. Energy 134 (2014) 229–238.

https://doi.org/10.1016/j.apenergy.2014.08.013 - Adil Wazeer, Apurba Das, Chamil Abeykoon, Arijit Sinha, Amit Karmakar, Phase change materials for battery thermal management of electric and hybrid vehicles: A review, Energy Nexus, Volume 7, 2022, 100131.

https://doi.org/10.1016/j.nexus.2022.100131 - Applied Thermoelectric Solutions LLC, How thermoelectric cooling works. Available:

https://thermoelectricsolutions.com/how-thermoelectric-cooling-works/ - Kim, J. Oh, H. Lee, Review on battery thermal management system for electric vehicles, Appl. Therm. Eng. 149 (2019) 192–212.

https://doi.org/10.1016/j.applthermaleng.2018.12.020 - Suresh Patil, J.-H. Seo, M.-Y. Lee, A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management, Energy Convers. Manage. 229 (2021) 113715.

https://doi.org/10.1016/j.enconman.2020.113715 - Zhu, Y. Fang, L. Su, Y. Fei, Experimental study on thermal performance of a pumped two-phase battery thermal management system, Int. J. Energy Res. 44 (6) (2020) 4664–4676.

https://doi.org/10.1002/er.5247 - Li, C. Zhang, Y. Zhao, G.J. Offer, M. Marinescu, Effect of thermal gradients on inhomogeneous degradation in lithium-ion batteries, Commun. Eng. 2 (1) (2023) 1–14.

https://doi.org/10.1038/s44172-023-00124-w - A. Hunt, Y. Zhao, Y. Patel, G.J. Offer, Surface cooling causes accelerated degradation compared to tab cooling for lithium-ion pouch cells, J. Electrochem. Soc. 163 (9) (2016) A1846.

https://doi.org/10.1149/2.0361609jes - United States Advanced Battery Consortium (USABC). Available:

https://uscar.org/download/50/publications/12727/thermal-management-rfpi-system-goals.pdf - Lu, J., Lyu, Y., Chen, B., & Wu, C., Accurate Measurement of the Internal Temperature of 280 Ah Lithium-Ion Batteries by Means of Pre-Buried Thermocouples, Batteries, 10(6), 184, 2024.

https://doi.org/10.3390/batteries10060184 - Hu, X., Xu, H., Ding, C., Tian, Y., & Yang, K., Numerical Study on the Thermal Behavior of Lithium-Ion Batteries Based on an Electrochemical Thermal Coupling Model, Batteries, 11(7), 280, 2025.

https://doi.org/10.3390/batteries11070280 - Kumar Thakur, R. Sathyamurthy, R. Velraj, R. Saidur, A.K. Pandey, Z. Ma, P. Singh, S.K. Hazra, S. Wafa Sharshir, R. Prabakaran, S.C. Kim, S. Panchal, H.M. Ali, A state-of-the art review on advancing battery thermal management systems for fast-charging, Appl. Therm. Eng. 226 (2023) 120303.

https://doi.org/10.1016/j.applthermaleng.2023.120303 - Wenxin Mei, Zhixiang Cheng, Yue Zhang, Jinhua Sun, Qingsong Wang, Comparative study of thermal stress and diffusion stress in lithium-ion batteries: A coupled electrochemical-thermal-mechanical modeling framework, Journal of Energy Storage, Volume 141, Part A, 2026, 119177.

https://doi.org/10.1016/j.est.2025.119177 - Wu, B., Yang, Y., Liu, D., Niu, C., Gross, M., Seymour, L., Lee, H., Le, P. M. L., Vo, T. D., & Deng, Z. D., Good practices for rechargeable lithium metal batteries, Journal of The Electrochemical Society, 166(16), A4141, 2019.

https://doi.org/10.1149/2.0691916jes - A. Wahab, A.-U.-H. Najmi, H. Senobar, N. Amjady, H. Kemper, and H. Khayyam, Immersion cooling innovations and critical hurdles in Li-ion battery cooling for future electric vehicles, Renew. Sustain. Energy Rev., vol. 211, p. 115268, 2025.

https://doi.org/10.1016/j.rser.2024.115268 - Christen, R., Rizzo, G., Gadola, A., & Stöck, M., Test Method for Thermal Characterization of Li-Ion Cells and Verification of Cooling Concepts, Batteries, 3(1), 3, 2017.

https://doi.org/10.3390/batteries3010003

Links that May Interest You

- How Thermoelectric Generators Work

- How Thermoelectric Cooling Works

- ParaThermic® Battery Thermal Management Technology

- VoltaTherm® Battery Thermal Management System (BTMS)

- PowerBeam™ Wireless Power Transfer Technology

- Our Thermoelectric Cooling and Thermoelectric Generator Work

- Our Thermoelectric Generator and Thermoelectric Cooling Services

- Our Thermoelectric and Advanced Thermal Technology

- Solar Thermoelectric Generator Case Study

- Thermoelectric Cooling Prototype Case Study

- Battery Thermal Management | Breaking the Physical Heat Limit

Did You Like This Post?

We would greatly appreciate it if you could leave a comment to let us know your thoughts on this post.

Your feedback and suggestions are highly valued and we welcome all comments and tips.

Thank you for taking the time to share your input with us.