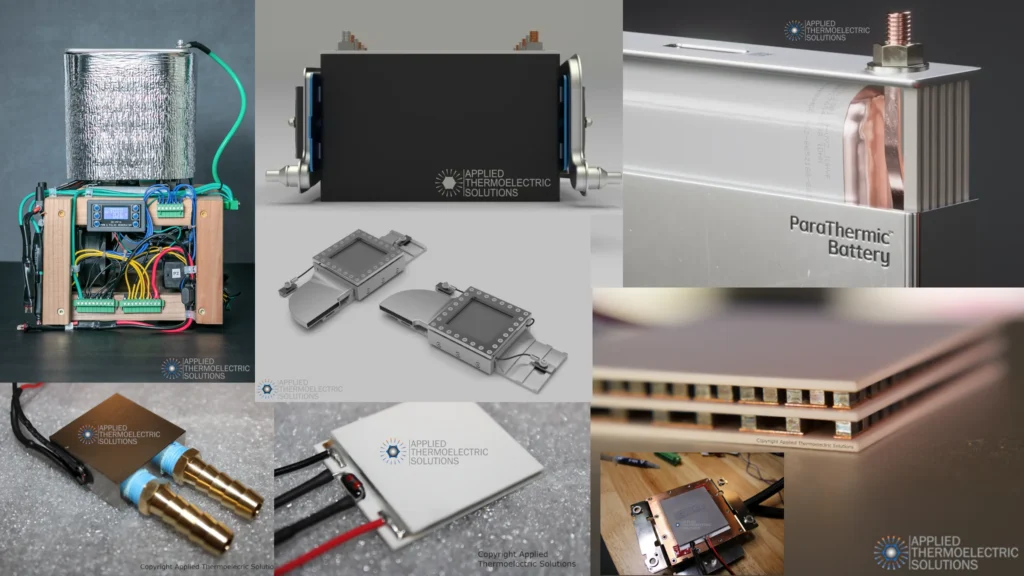

Solid State Cooling System Design & Thermoelectric Prototype Development

System-Level Engineering for Advanced Thermal Management Systems

System-Level Engineering and Prototype Development

Cooling system design and thermoelectric cooling system integration for advanced solid state thermal and power applications.

Applied Thermoelectric Solutions develops solid state cooling systems and thermoelectric cooling system architectures for OEMs, advanced hardware teams, energy innovators, and research-driven organizations requiring validated thermal performance and structured prototype development.

Our solid state cooling system design approach ensures each thermal management system is optimized for heat flux, efficiency, reliability, and integration constraints.

Whether your application involves precision cooling, thermal management, or solid-state power generation, we engineer complete cooling system designs built for real-world operation.

If conventional cooling technologies or off-the-shelf modules cannot meet your requirements, we help you move from concept through structured prototype development to validated hardware with confidence.

What We Deliver

Our solid state cooling system design and thermoelectric prototype development services support projects from early feasibility through validated thermal management system hardware.

Capabilities include:

-

System architecture and thermal management design

-

Thermoelectric cooling system design

-

Solid state cooling integration

-

Thermoelectric module selection or custom development

-

Advanced modeling and simulation

-

Heat transfer optimization

-

Mechanical integration

-

Controls and power electronics integration

-

Prototype build and validation testing

Every solution is engineered to meet defined performance targets while reducing technical and financial risk.

Solid State Cooling System Design

Effective solid state cooling system design requires more than selecting a thermoelectric module. It begins with full system architecture development, where thermal loads, heat flux density, ambient conditions, and control requirements are evaluated together.

Our solid state cooling system design process focuses on optimizing thermal pathways from the heat source to the heat rejection interface. This includes cold plate geometry, heat exchanger selection, interface materials, mechanical integration, and electrical architecture.

Thermal management system performance depends on minimizing parasitic losses and ensuring efficient heat transfer under real operating conditions. We evaluate airflow or liquid cooling strategies, transient thermal response, and dynamic control behavior to ensure stable operation.

Controls integration is equally critical. Power electronics, feedback sensors, and control algorithms must be designed to maintain tight temperature regulation without compromising efficiency or reliability.

Each cooling system design is validated through simulation and hardware testing to confirm performance, durability, and integration readiness before production transition.

When Should You Consider a Custom Thermoelectric Prototype?

You may benefit from system-level thermal engineering when:

-

Heat flux exceeds conventional cooling limits

-

Tight temperature control is required

-

Reliability is mission-critical

-

Form factor constraints prevent traditional refrigeration

-

Off-the-shelf cooling modules fail to meet performance targets

-

Differentiated thermal capability creates competitive advantage

Early engineering analysis often prevents costly redesign cycles later in development.

Our Development Process

A structured cooling system design and engineering process reduces uncertainty and ensures your solid state cooling system prototype performs as expected.

- Technical Consultation

We evaluate your application, constraints, performance goals, and operating environment to determine feasibility. - Requirements Definition

Thermal loads, efficiency targets, electrical needs, size constraints, and durability requirements are clearly established. - System Architecture

We design the complete cooling system or thermoelectric solution, optimizing heat flow paths, module configuration, and thermal interfaces. - Modeling and Simulation

Advanced simulation tools predict real-world behavior before hardware is built. - Detailed Design

Mechanical structures, heat exchangers, cold plates, electronics, and interfaces are finalized. - Prototype Build and Validation

Physical prototypes undergo rigorous performance testing under realistic operating conditions.

The result is a validated system you can confidently evaluate and prepare for production.

See an example in our thermoelectric cooling system prototype case study.

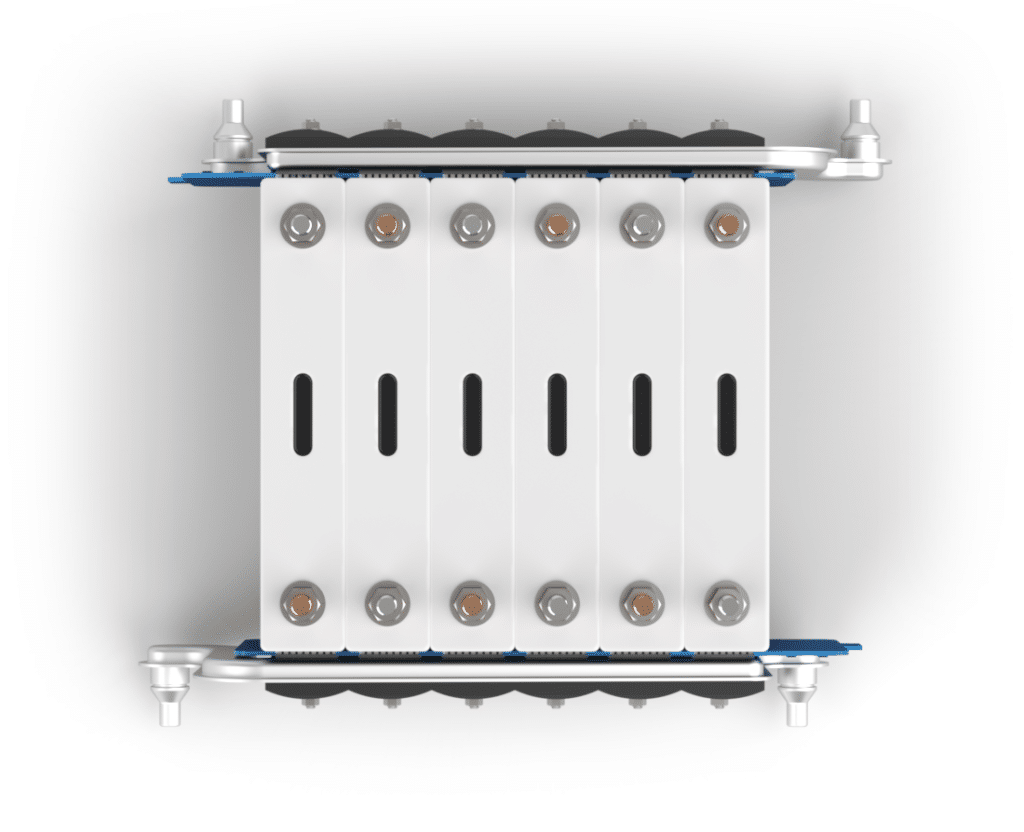

Battery Thermal Management Systems

Thermoelectric and solid-state cooling architectures engineered to improve temperature control, safety, and lifecycle performance in lithium-ion modules and packs.

See our VoltaTherm® battery thermal management system and ParaThermic® battery architecture

Wireless Power for Rotating Equipment

Solid-state thermoelectric power systems designed to deliver reliable energy to rotating sensors supporting predictive maintenance.

Explore our PowerBeam™ wireless power transfer technology.

Advanced Thermal Platforms

Integrated cooling and heating systems for demanding environments where conventional technologies fall short.

See our thermoelectric cooling case studies.

Most Projects Require More Than a Module

Many teams begin by searching for a thermoelectric module. However, successful cooling system design requires a fully engineered thermal management system.

Successful products require a fully engineered cooling system.

The module is the engine.

The system is the vehicle.

Without system-level thermal design, component capability rarely translates into product performance.

Typical system elements include:

-

Heat exchangers and cold plates

-

Heat sinks and fluid systems

-

Electrical architecture

-

Control systems

-

Structural packaging

-

Validation and reliability testing

A system-level approach is often the difference between a concept that struggles and a prototype that succeeds.

Off-the-Shelf vs Custom Thermoelectric Modules

Off-the-shelf modules perform well when requirements align with standard specifications such as cooling capacity, voltage, form factor, and operating range.

High-performance cooling system design often demands customization.

Custom thermoelectric modules allow optimization of:

-

Semiconductor geometry

-

Element count

-

Footprint and thickness

-

Materials and metallization

-

Thermal pathways

System expertise transforms component capability into validated product performance.

Why Engineering Teams Choose Applied Thermoelectric Solutions

What Sets Us Apart

- Deep Technical Expertise

Decades of thermoelectric and solid-state thermal engineering experience guide every design decision. - System-Level Thinking

We engineer complete cooling system architectures. - Risk-Reducing Development

Our gated process validates each stage before major investment. - Advanced Modeling Capability

In-house simulation shortens development cycles. - Collaborative Engagement

We operate as an extension of your technical team. - Performance Focused

Every prototype is optimized for real-world operation.

Applied Thermoelectric Solutions (ATS) has helped me advance my idea

Applied Thermoelectric Solutions has helped me to bring to life a concept I have had for a long time and never had time or expertise to pursue. Alfred helped me to frame the questions that needed to be answered and proposed a scope of work to evaluate feasibility. To my delight we are ready to go the next step and look at options to decide upon a prototype. I would never have accomplished this without ATS and Alfred’s help. I am in process of applying for a grant to do further research and will continue to use ATS for scientific evaluations. Thank you ATS team and Alfred Piggott.

Engagement Scope and Industry Focus

Industries We Support

Our solid state cooling and thermoelectric cooling system design services support technically demanding applications across:

-

Advanced energy systems

-

Battery and electric vehicle platforms

-

Aerospace and defense hardware

-

Industrial electronics and power systems

-

Medical and scientific instrumentation

-

Precision manufacturing and semiconductor equipment

If your application requires validated thermal performance beyond conventional cooling technologies, we can support feasibility through prototype development.

Typical Engagement Scope

Most projects begin with a structured feasibility or architecture evaluation to define system requirements, heat flux limits, and integration constraints.

Typical engagements range from:

-

Early-stage feasibility studies

-

System architecture and modeling

-

Cooling system design optimization

-

Prototype hardware development and validation

We operate as an extension of your engineering team, aligning technical milestones with your product development roadmap.

Prototype Timeline

Project timelines vary depending on system complexity, thermal load, and integration requirements.

Typical feasibility evaluations are completed in 4–8 weeks.

Prototype development timelines typically range from 8–16 weeks, depending on validation requirements and hardware iteration needs.

Early engineering alignment significantly reduces downstream redesign risk and accelerates production readiness.

Start Your Thermoelectric Prototype

If you are evaluating a solid state cooling concept, developing a thermoelectric system, or pushing beyond the limits of conventional thermal technologies, we can help you move forward with clarity and confidence.

Explore our thermoelectric engineering services or review our recent system development work.

Frequently Asked Questions

What is a solid state cooling system?

A solid state cooling system is a thermal management system that uses thermoelectric devices to move heat without compressors, refrigerants, or moving mechanical components. Instead of vapor compression, heat is transferred using semiconductor materials when electrical current is applied. Solid state cooling systems are compact, precise, and well suited for applications requiring tight temperature control or high reliability.

How is thermoelectric cooling different from vapor compression?

Thermoelectric cooling systems rely on solid-state heat pumping through semiconductor junctions, while vapor compression systems depend on refrigerant phase change and mechanical compressors. Solid state cooling offers precise temperature control, orientation independence, reduced vibration, and compact integration. Vapor compression typically offers higher efficiency at large scale but is less adaptable for compact, high-precision cooling system design.

When should a custom cooling system be developed?

A custom cooling system should be developed when heat flux exceeds conventional limits, tight thermal control is required, space constraints prevent traditional refrigeration, or when off-the-shelf thermoelectric modules cannot meet performance targets. System-level engineering ensures the full thermal management system is optimized rather than relying on component-level capability alone.

Can thermoelectric cooling scale for high heat flux applications?

Yes, thermoelectric cooling can be engineered for higher heat flux environments when system architecture, thermal pathways, heat exchangers, and controls are properly optimized. Successful scaling depends on integrated cooling system design rather than module selection alone. Advanced modeling and validation are critical to ensure reliable performance under demanding operating conditions.