The Author – Founder and CTO

Alfred Piggott is the Founder and CTO of Applied Thermoelectric Solutions, specializing in thermoelectrics, battery thermal management, and energy conversion. With more than 30 years of engineering experience, he develops advanced cooling, power generation, and high-heat-transfer battery technologies. Alfred holds multiple patents, has published award-winning research, and shares practical insights from ongoing modeling, system development, and prototype build work.

Key Takeaways

- Thermoelectric cooling systems can deliver meaningful performance beyond small devices when engineered correctly.

- First-build performance was strong and aligned with model predictions.

- Noise, power, and packaging requirements can be balanced successfully.

- There is clear headroom path to even better performance.

- Thermoelectrics remain a viable option for applications where reliability, control, and solid-state operation matter.

Why a Thermoelectric Cooling System Prototype Was Needed for This Application

Thermoelectric cooling is often dismissed as impractical beyond small or low-power applications. With the right engineering approach, however, thermoelectrics can deliver meaningful performance in larger and more demanding systems, while offering advantages in control, reliability, and system simplicity that traditional refrigerant-based cooling cannot.

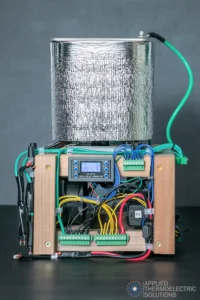

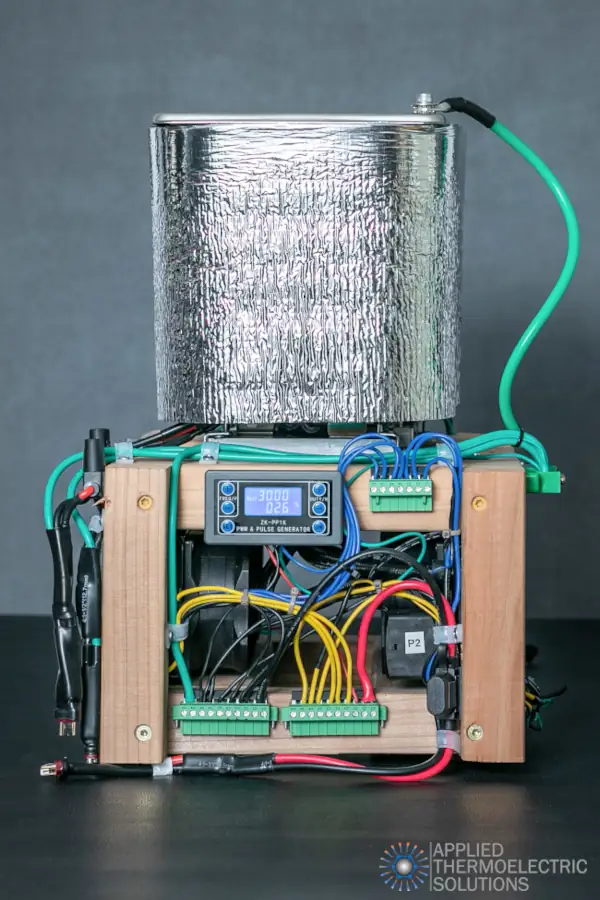

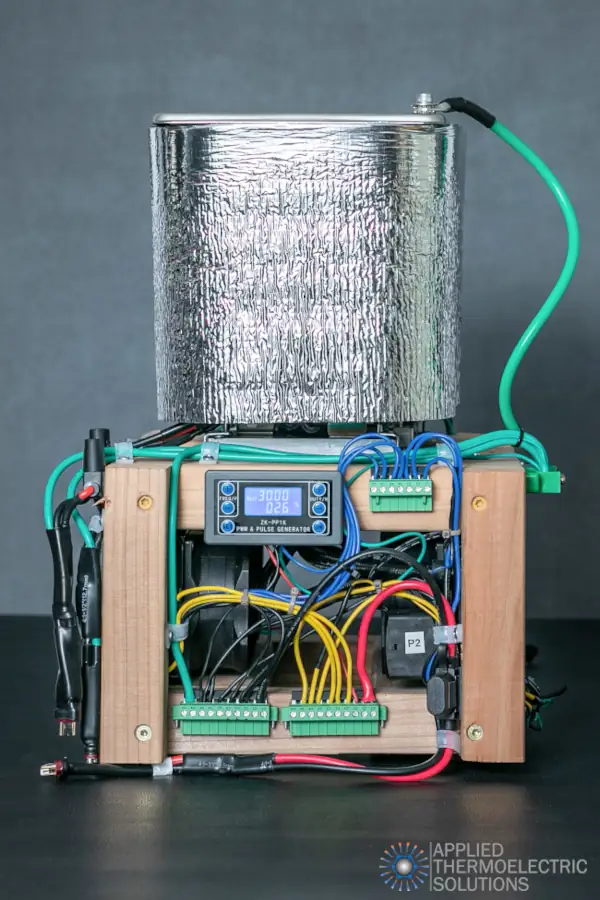

Recently, we designed, built, and delivered a proof-of-concept thermoelectric cooling system prototype for a customer with extensive experience developing refrigerant-based precision temperature control systems for demanding laboratory and industrial applications. The customer provided detailed application requirements and performance targets, while we developed the thermoelectric system concept and led the system-level engineering, modeling, and prototype development. This combination allowed us to address a challenging large-volume cooling requirement and validate the concept with working hardware.

Images are shared with customer permission and do not disclose confidential design details.

Engineering Requirements for This Thermoelectric Cooling System Design

The customer approached us with a demanding problem that required:

- Cooling a large-volume stainless steel tank

- Tight packaging constraints

- Defined acoustic (noise) limits

- Practical power consumption targets

- A functional prototype that provides real-world learning, not a lab curiosity

In many environments, thermoelectrics would simply be ruled out for this type of problem. High thermal mass, stainless steel, constrained space, and acoustic requirements create a very difficult engineering environment, especially when you need real hardware and not just simulations.

The goal was very clear. Prove feasibility in real hardware, do it quickly, and avoid long multi-iteration development cycles if possible.

Our Thermoelectric Cooling System Engineering Approach

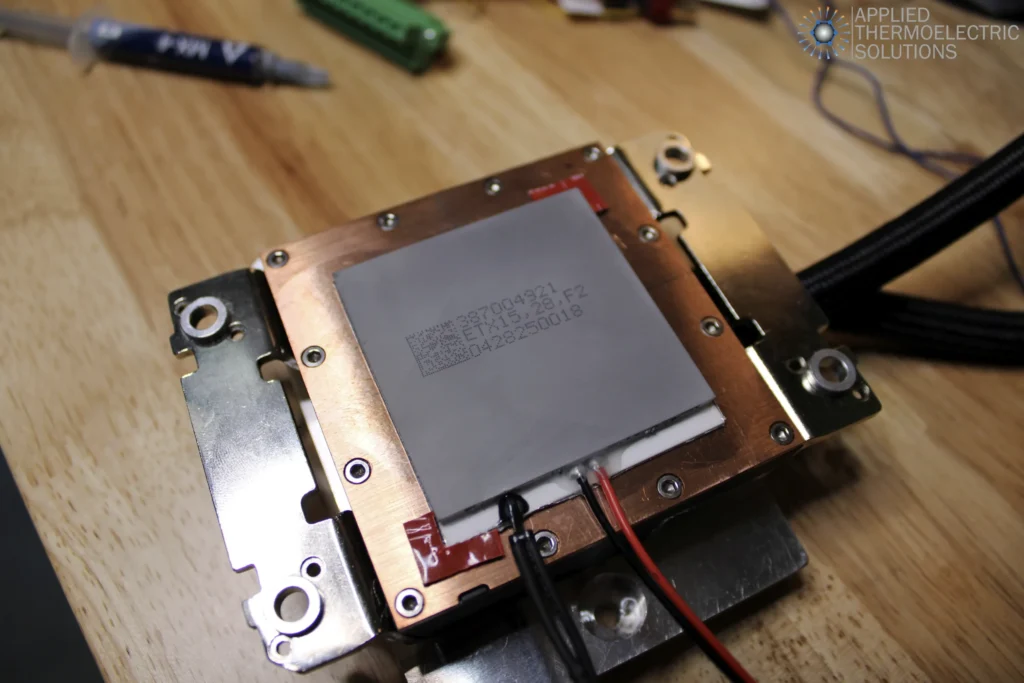

We approached this as a complete thermoelectric cooling system design problem, not a simple module selection task. That meant focusing on how everything worked together.

Our Thermoelectric Cooling System Engineering Approach

- System-level thermal modeling to predict realistic performance

- Careful optimization of heat paths and interfaces

- Component selection that balanced cost, performance, and availability

- Design that could be refined into a product, not a one-off science project.

By combining thermoelectric physics expertise, practical system engineering, and our published research in advanced battery thermal behavior, we focused on building something that would work correctly the first time instead of relying on trial-and-error development.

Thermoelectric Cooling Prototype Results and Performance

The prototype was designed, assembled, shipped, and successfully received by the customer. The following is a brief summary of outcomes and observations.

Packaging and Integration

We came very close to meeting the tight packaging requirements on the first build. With custom plumbing and custom heat exchangers in a future revision, packaging efficiency could be pushed even further.

Cooling Performance

This prototype was intentionally designed with manufacturability and straightforward assembly in mind. A higher-performance configuration is possible, but the customer agreed that a production-friendly approach was the right choice for this phase. Even so, the cool-down performance was very close to the target, confirming that our engineering models closely matched real-world behavior.

Noise and User Experience

Testing was performed at the maximum noise level specified by the customer. Our analysis also indicates that it may be possible to reduce acoustic levels further without a meaningful loss in cooling performance, if that becomes important to the use case.

Power Optimization Headroom

The prototype is not yet being operated at its most power-efficient point. There is clear opportunity to reduce electrical power consumption while maintaining strong performance. This provides options as the program evolves.

Opportunities for Further Improvement

With refinement of the cold-side thermal interface, our modeling suggests that cool-down time could be improved even further.

Cost and Product Considerations

As with any program moving from feasibility toward productization, cost optimization will require further discussion with the customer. The important takeaway is that this concept has demonstrated performance that justifies deeper development consideration.

What This Thermoelectric Cooling System Prototype Demonstrates

Many teams assume that thermoelectrics only make sense for very small devices or for niche low-power applications. This project demonstrates that thermoelectric cooling systems can scale to meaningful and demanding applications when they are engineered correctly.

Thermoelectric systems also offer compelling benefits:

- Solid-state reliability with no compressors and no refrigerants

- Precise temperature control

- Ability to both heat and cool using the same system

- Compact and application-specific design possibilities

- Often simpler mechanical architecture

The most significant result is that we achieved strong performance on the first hardware build. This reduces development risk, shortens timelines, and helps customers move forward with greater confidence.

Considering a Thermoelectric Cooling System Prototype? Let’s Talk.

If you are considering a thermoelectric cooling solution and want to understand feasibility, performance potential, and risk, we can help. We provide system-level thermoelectric engineering, modeling, and prototype development to support real product decisions. Contact us to discuss your application.

Frequently Asked Questions

What information do you need from us to evaluate feasibility?

Every thermoelectric cooling system project is unique, so the information we need depends on your specific application. We typically review heat load, temperature targets, space and packaging constraints, power availability, acoustic limits, and the operating environment. The easiest next step is to contact us so we can schedule a brief call. We will guide you through what is needed and help determine whether a thermoelectric cooling solution is feasible for your system.

What does the typical development process look like?

We begin by understanding your goals, performance requirements, and constraints. From there, our process usually follows a structured path: concept development, thermal modeling and simulation, detailed system design, and then building and testing a thermoelectric cooling prototype. This staged approach keeps things efficient, reduces uncertainty, and ensures each step is grounded in solid engineering.

How quickly can you deliver a proof-of-concept thermoelectric prototype?

Timeline depends on application complexity and how defined project requirements are. When requirements are clear, we are able to move quickly and efficiently. In this example project, the prototype was delivered rapidly and performed well on the first build without multiple redesign cycles. Contact us to discuss your application and we can provide a realistic timeline.

What level of risk should we expect with a thermoelectric prototype?

There is always some risk in advanced engineering development, but our approach is designed to reduce it significantly. We work in logical stages, apply advanced thermal modeling and simulation before building hardware, and leverage deep experience with thermoelectric cooling systems. This helps minimize trial-and-error development and improves the likelihood of strong first-build performance.

Do we need to commit to a full development program right away?

No. Our work is structured in stages so you can make decisions with clarity and confidence. A feasibility evaluation or modeling effort is often the right starting point before moving into full thermoelectric cooling system development.

Links that May Interest You

- How Thermoelectric Generators Work

- How Thermoelectric Cooling Works

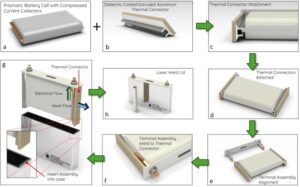

- ParaThermic® Battery Thermal Management Technology

- VoltaTherm® Battery Thermal Management System (BTMS)

- PowerBeam™ Wireless Power Transfer Technology

- Our Thermoelectric Cooling and Thermoelectric Generator Work

- Our Thermoelectric Generator and Thermoelectric Cooling Services

- Our Thermoelectric and Advanced Thermal Technology

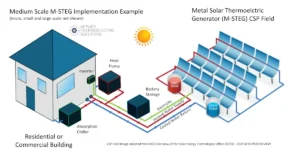

- Solar Thermoelectric Generator Case Study

- Thermoelectric Cooling Prototype Case Study

- Battery Thermal Management | Breaking the Physical Heat Limit

Did You Like This Post?

We would greatly appreciate it if you could leave a comment to let us know your thoughts on this post.

Your feedback and suggestions are highly valued and we welcome all comments and tips.

Thank you for taking the time to share your input with us.