Thermoelectric Engineering Services

Applied Thermoelectric Solutions provides thermoelectric engineering, modeling, and R&D services supporting solid-state thermoelectric cooling, thermoelectric generator (TEG) systems, and heat-to-electric energy conversion — from well-defined engineering analysis through the development of novel solutions when conventional approaches fall short, generating the data and insight required to guide confident technical decisions.

This page outlines our core thermoelectric services, spanning physics-based analysis, prototype development, validation, and innovation for cooling, power generation, and advanced thermal systems.

Expert Technical Guidance from Concept Through Implementation

“We brought in Applied Thermoelectric Solutions to assist with our client’s cutting-edge, non-polluting technology, which generates heat and converts it into electricity using thermoelectrics.

We engaged their technical consulting services, and they worked directly with our client, led by Alfred, the founder and CTO. Applied Thermoelectric Solutions went above and beyond by not only reviewing and refining the thermoelectric components but also providing invaluable feedback on the overall product design.

Their expertise helped optimize various aspects of the technology, from the initial concept to practical implementation. The insights they shared played a key role in elevating the entire product, and our client was thrilled with the results. We highly recommend Applied Thermoelectric Solutions for their outstanding technical expertise and their comprehensive support in advancing our client’s cutting-edge technology.”

Why Applied Thermoelectric Solutions?

Applied Thermoelectric Solutions provides thermoelectric engineering, modeling, and R&D services supporting solid-state cooling, thermoelectric generator systems, and heat-to-electric energy conversion.

Our work begins with experience-driven, physics-based analysis and system-level understanding to establish realistic performance limits, guide design decisions, and reduce development risk.

Our Core Engineering Services

Thermoelectric Feasibility Studies and System Analysis

Early-stage thermoelectric analysis to establish realistic performance limits and guide development decisions.

Thermoelectric Modeling & Simulation

Thermal, electrical, and coupled electrothermal modeling used to guide thermoelectric system design and reduce iteration risk.

Thermoelectric Research and Development

Applied R&D advancing thermoelectric device architectures, interfaces, and system-level performance.

Thermoelectric Prototype Development

Design and development of thermoelectric hardware and system prototypes to generate actionable performance data.

Thermoelectric Validation & Testing

Experimental testing to characterize thermal, electrical, and system-level behavior under realistic operating conditions.

Thermoelectric Engineering Consulting

Technical consulting for organizations evaluating thermoelectric technologies, advanced cooling strategies, or energy-conversion concepts.

Innovation and Invention Services for Thermoelectric Systems

Development of novel, non-obvious technical solutions when established engineering approaches cannot meet performance or integration requirements.

Thermoelectric Applications in Battery Thermal Management

Application of thermoelectric and ParaThermic® high-heat-transfer (HHT) designs to battery systems where heat removal limits performance.

Commercialization Support and Technical Due Diligence

Technical assessment supporting funding decisions, grant applications, and product development planning.

Thermoelectric Feasibility Studies and System Analysis

Early-stage thermoelectric analysis to determine whether an approach is technically feasible, commercially realistic, and worth pursuing before committing to development. This service helps clients make confident go/nogo decisions, quantify fundamental limits, and avoid costly prototype iterations.

Typical focus areas include:

Realistic performance limits and constraints to guide expectations

Key thermal, electrical, and cost tradeoffs that shape design boundaries

Clear go/no-go guidance and recommended development paths

Related work:

Expert Support in Thermoelectric Energy Solutions and Feasibility Studies

“As the CEO of STEMero, I’ve had the privilege of working with Applied Thermoelectric Solutions (ATS) on a project that’s been close to my heart for years, bringing to life a concept for Metallic Solar Thermoelectric Generators (M-STEGs). Alfred Piggott and the ATS team were instrumental in helping me refine the key questions and shape a comprehensive feasibility study that moved us from concept to practical evaluation.

Their expertise in thermoelectric technologies, coupled with their ability to integrate scientific and economic factors, was invaluable. We worked closely with ATS to assess material costs, energy performance, and sustainability factors for M-STEGs, setting the stage for prototype development and crafting materials to secure external funding.

I’m currently applying for grant funding to continue research, and I’m excited to carry on our partnership with ATS for ongoing scientific evaluations and technical consulting. I would not have gotten to this stage without their dedicated support and innovation.

I highly recommend ATS for anyone seeking cutting-edge renewable energy solutions, particularly in thermoelectric power generation and solar energy innovations. Their professionalism and expertise make them a trusted partner for any energy project”

Diane Mero, Founder and CEO, STEMero

Thermoelectric Modeling & Simulation

Proprietary physics-based thermoelectric and electrothermal modeling used to guide design decisions, quantify performance tradeoffs, and reduce costly trial-and-error prototyping. These simulations help teams understand system behavior before hardware is built and reduce technical risk throughout development.

Capabilities include:

Thermal and electrothermal modeling to identify dominant heat-transfer limits

Electrical performance and efficiency analysis to inform operating tradeoffs

System-level and coupled multiphysics simulations to improve architecture selection and reduce iteration cycles

Related work:

Thermoelectric Research and Development

Applied thermoelectric R&D that advances device architectures, interfaces, and system-level performance for applications that require more than incremental improvement. This work deepens understanding of difficult thermal challenges and unlocks solutions that standard engineering methods cannot reach.

R&D activities may include:

Investigation of new device and module architectures

Interface and heat-transfer optimization for boundary-limited systems

System-level performance exploration to inform future design strategies

Focused literature and technical trend review to identify emerging opportunities

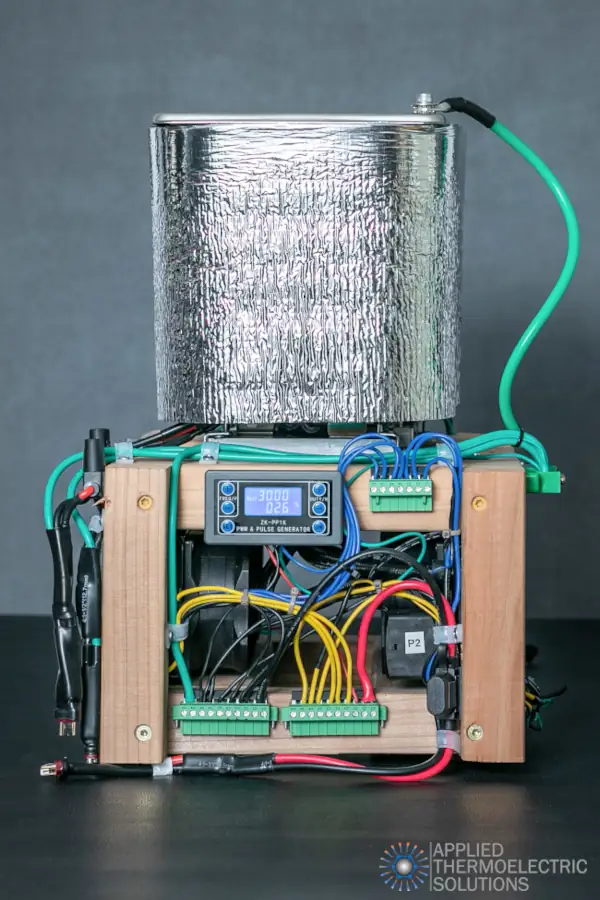

Thermoelectric Prototype Development

Design and development of thermoelectric hardware and thermoelectric system prototypes to generate actionable performance data, validate analytical predictions, and accelerate decision making. Rapid prototyping provides early insight into manufacturability, integration constraints, and real-world behavior.

Prototype work can help you:

Translate models into physical hardware for verification

Evaluate integration challenges early

Derive data that sharpens subsequent design iterations

Reduce development time and uncertainty for product decisions

Related work:

Thermoelectric Validation & Testing

Experimental testing to confirm real-world thermal, electrical, and system-level performance against design expectations, reduce prototype risk, and support critical decisions. Validation testing reveals failure modes, performance limits, and boundary behavior that models alone cannot fully predict.

Testing services include:

Verification of thermal and electrical performance under realistic conditions

Assessment of system behavior at design limits

Model-to-test correlation to improve confidence in simulation-driven designs

Data support for design freeze, qualification, or commercialization planning

Thermoelectric Engineering Consulting

Technical thermoelectric consulting for organizations evaluating thermoelectric technologies, advanced cooling strategies, or energy-conversion concepts. Applied Thermoelectric Solutions consulting provides independent assessment, technical framing, risk analysis, and roadmap guidance to align engineering choices with business objectives.

Consulting engagements can deliver:

Independent evaluation of technical viability

Risk and uncertainty analysis to improve investment decisions

Development planning that aligns technical effort with product strategy

Prioritized recommendations based on physics and system constraints

Related work:

Innovation and Invention Services for Thermoelectric Systems

Most engineering challenges are addressed through careful analysis, modeling, and established design approaches. In some cases, however, required performance, safety, or cost targets depend on creating a novel solution rather than refining existing ones. Innovation and Invention Services are offered specifically for these situations, building on standard engineering work when conventional approaches are insufficient.

This work focuses on developing novel thermoelectric and thermal system architectures, interfaces, or operating concepts for problems where existing solutions reach fundamental limits. It draws on deep domain experience, first-principles reasoning, and structured creative problem solving to identify approaches that are not immediately obvious through standard engineering workflows.

These engagements may involve:

Creation of new thermoelectric or thermal system architectures

Exploration of unconventional heat-transfer pathways or interfaces

Concept-level invention aimed at breaking performance, safety, or cost bottlenecks

When invention work results in broadly applicable solutions or product architectures, engagements may transition to a licensing or partnership model, aligning incentives around long-term development and commercialization.

Related work:

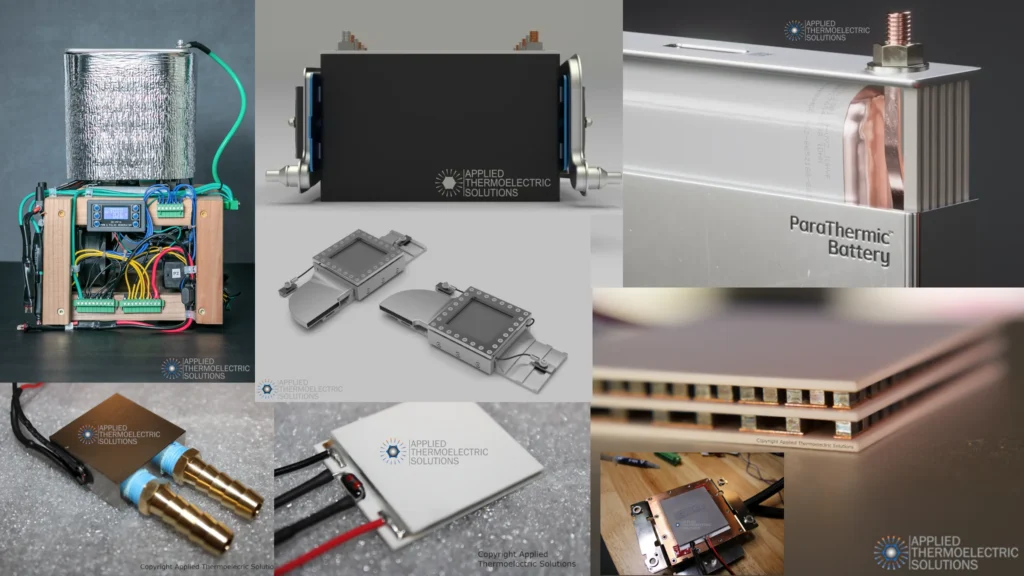

Thermoelectric Applications in Battery Thermal Management

Application of thermoelectric and ParaThermic® high-heat-transfer (HHT) designs to thermoelectric battery thermal management systems where heat removal limits performance, reliability, or charging capability. Applied Thermoelectric Solutions battery work bridges thermal analysis, prototyping, and validation to accelerate product readiness while managing risk.

Battery services help you:

Understand thermal behavior of battery systems under real-world conditions

Evaluate novel thermal architectures using physics-based models

Validate thermoelectric battery thermal management concepts with prototype data

Reduce uncertainty in thermal design and integration decision making

Related work:

Commercialization Support and Technical Due Diligence

Technical assessment used to support funding, licensing, and product development decisions involving thermoelectric or advanced thermal technologies. This service helps investors, partners, and technical teams understand what is realistically achievable, what risks remain, and where development effort should be focused.

Commercialization and due diligence engagements are designed to reduce technical uncertainty, identify hidden constraints, and provide clear, defensible guidance before major commitments are made.

Typical support includes:

Independent technical evaluation for investors, partners, or internal decision makers

Assessment of claimed performance against physics-based limits and available data

Identification of technical risks, development gaps, and integration challenges

Support for SBIR, design contest and government funding proposals, including technical narratives and feasibility framing

Development roadmaps that align technical milestones with commercialization objectives

Related work:

How We Typically Work With Clients,

Our process typically proceeds through four main steps:

Problem framing and constraints definition

Establishing clear performance targets, constraints, and success criteria before development begins.Physics-based analysis and modeling

Quantifying limits, tradeoffs, and sensitivities to guide design decisions and reduce iteration risk.Prototype or validation strategy

Selecting the most effective path to generate data, confirm assumptions, and de-risk development.Decision support and next technical steps

Translating results into clear recommendations for continued development, redesign, or go/no-go decisions.

Frequently asked Questions (FAQ)

Do you only work on novel or invention-level projects?

No. Most engagements involve well-defined engineering analysis, modeling, prototype development, or validation. Innovation and invention work is pursued selectively when conventional approaches cannot meet performance, safety, or integration requirements.

At what stage of development do you typically get involved?

We work across the full development cycle, from early feasibility studies and modeling through prototype development, testing, and commercialization support. Engagements are tailored to the technical questions that need to be answered at each stage.

Do you provide hardware development or only analysis?

In addition to modeling and analysis, we design and develop custom thermoelectric hardware and system prototypes to generate real performance data and validate design assumptions.

What types of organizations do you typically work with?

Clients include startups, established product companies, research organizations, and government-funded programs evaluating or developing thermoelectric and advanced thermal systems.

How do thermoelectrics fit into battery applications?

Thermoelectric approaches are applied selectively in battery systems where internal heat removal, transient behavior, or system integration limits performance. This includes work related to ParaThermic® high-heat-transfer battery architectures.

Experience & applications

Our work spans thermoelectric cooling, power generation, and advanced battery thermal management across feasibility studies, prototypes, and novel architectures.

Projects range from laboratory test systems and custom thermoelectric hardware to ParaThermic® high-heat-transfer battery concepts and solid-state thermal management solutions developed for performance-limited applications.

Not sure which service you need?

We often help clients define the right technical path before committing to development.