Our Work: Thermoelectric Engineering Projects

Overview

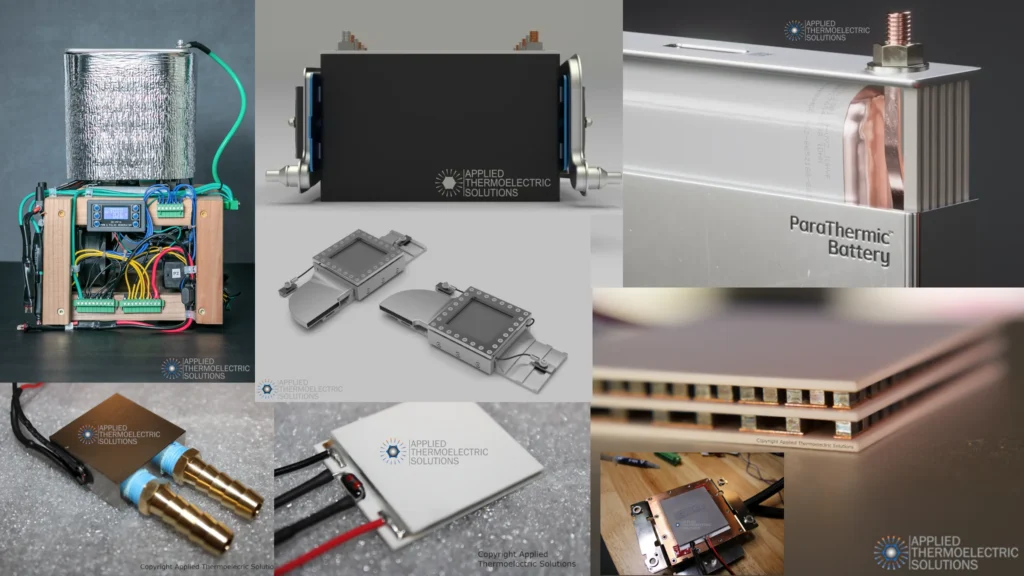

Our work highlights Applied Thermoelectric Solutions’ engineering projects spanning solid-state cooling, thermoelectric power generation, and advanced thermal system design.

These projects include feasibility studies, prototype development, and system-level evaluations for commercial and research applications.

Thermoelectric Cooling Projects

Representative projects focused on solid-state cooling, high heat-flux thermal management, and custom thermoelectric cooling system design.

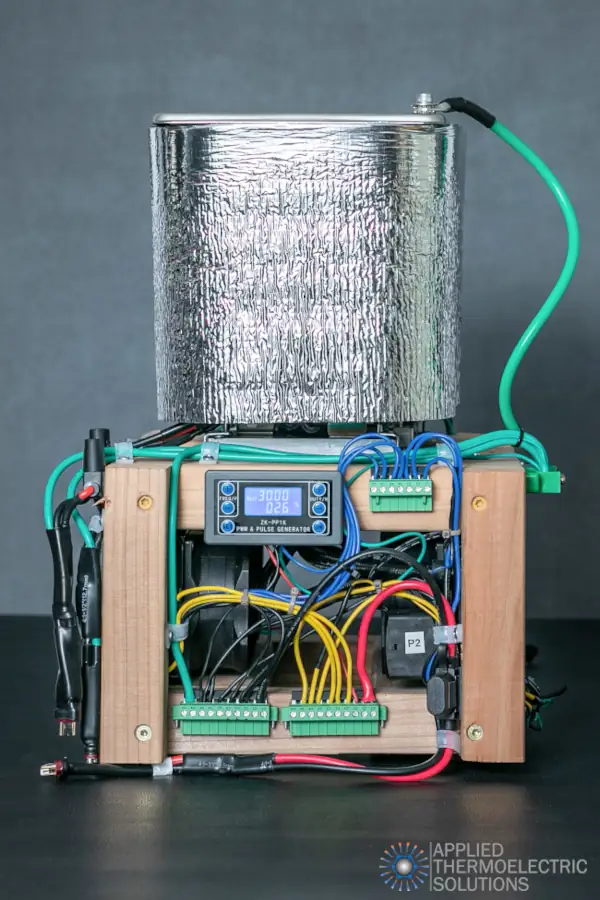

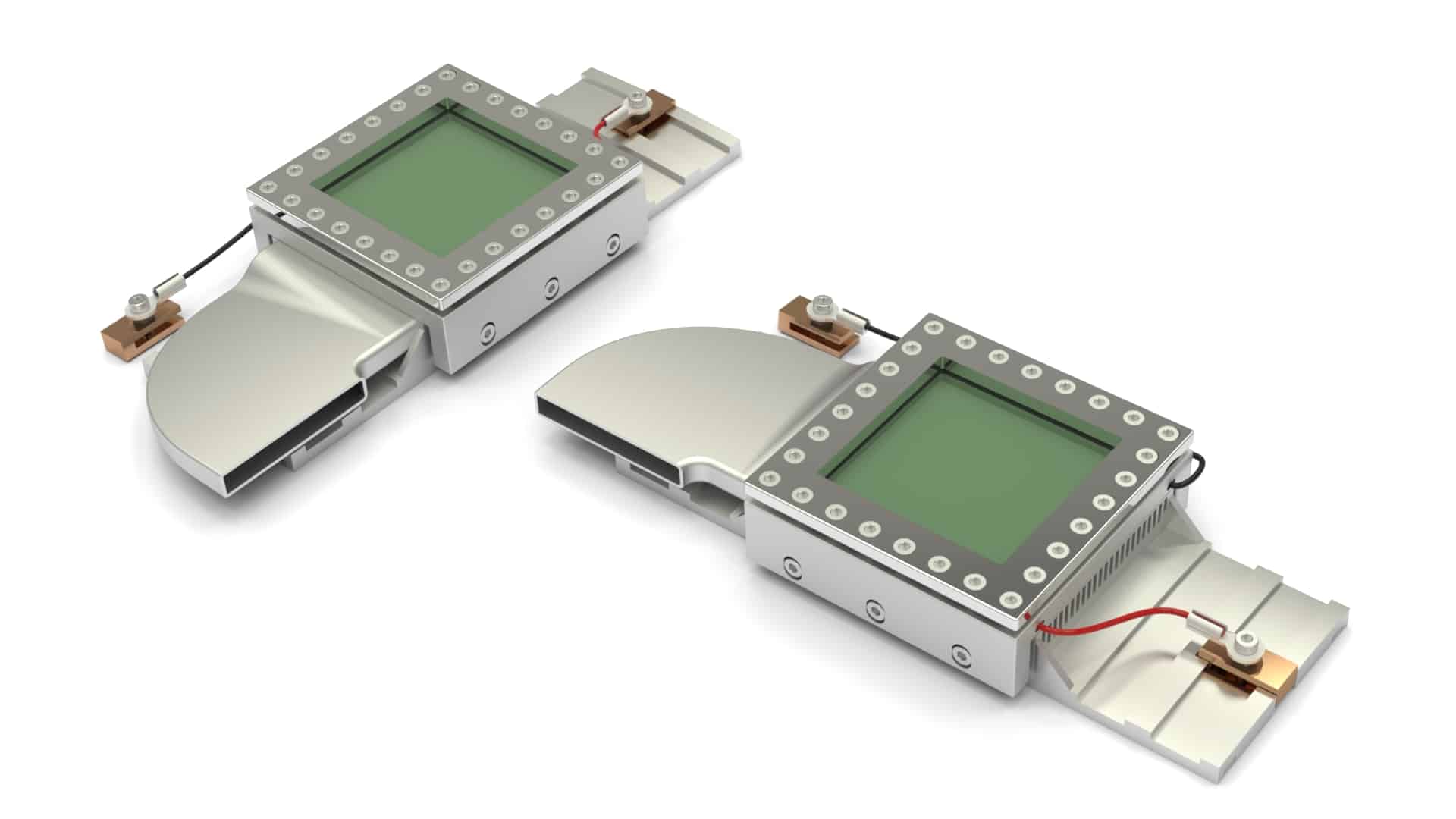

Custom Thermoelectric Cooling System Prototype (Proof-of-concept)

This prototype demonstrates a high-performance thermoelectric cooling system designed to handle demanding thermal loads under real operating conditions. The system integrates thermoelectric modules, control electronics, and mechanical packaging to validate performance, efficiency, and controllability. It serves as a proof-of-execution platform for custom thermoelectric cooling solutions in commercial and industrial applications.

Engineering Insight Beyond Components

“Applied Thermoelectric Solutions went beyond reviewing thermoelectric components, providing critical insight into overall system design and practical implementation. Their technical guidance significantly improved the final product and exceeded expectations.”

Finn Aretz

Operations Lead

How Thermoelectric Cooling Works

Thermoelectric cooling uses solid-state devices to pump heat directly through a material when an electrical current is applied. By controlling current direction and magnitude, heat can be actively removed, redistributed, or precisely regulated without moving parts, fluids, or compressors. This approach enables compact, reliable thermal control for electronics, batteries, and high heat-flux components where traditional cooling methods are impractical or insufficient.

Related Thermoelectric Cooling Research

Supporting research and technical publications underpinning advanced thermoelectric cooling system design, performance optimization, and transient thermal control.

Thermoelectric Power Generation (TEG)

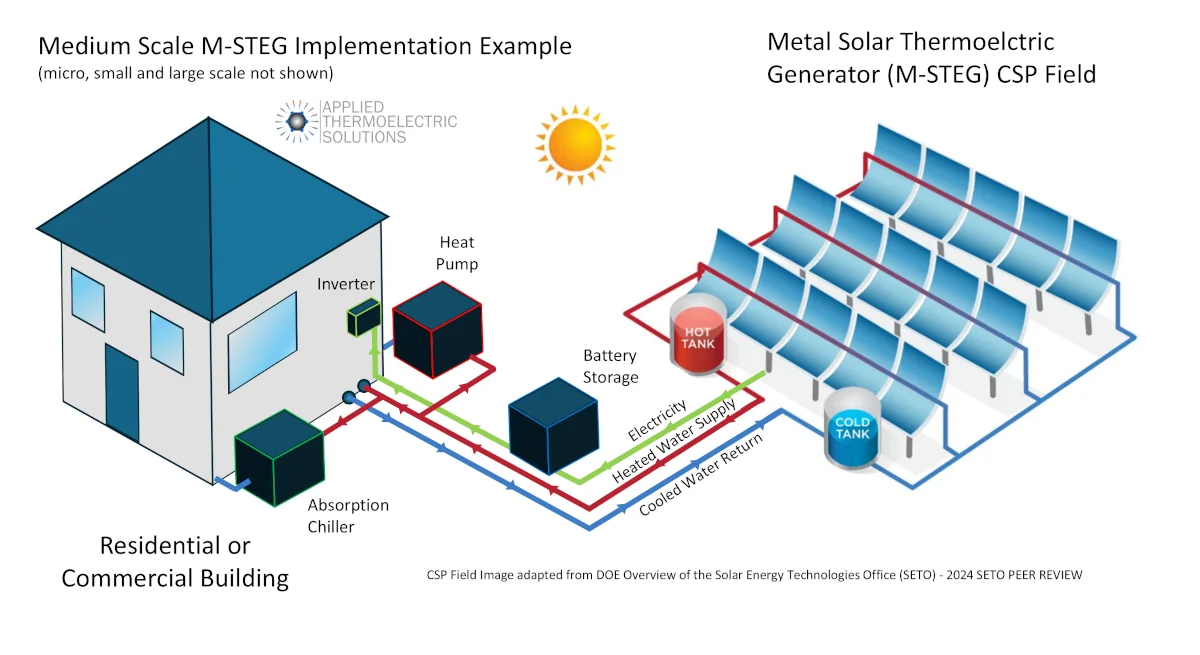

Applied Thermoelectric Solutions’ thermoelectric generator projects exploring solid-state power generation from solar and waste heat sources at the system level.

Solar Thermoelectric Generator Case Study

This case study evaluates metallic thermoelectric generators integrated with concentrated solar thermal systems as a solid-state power generation approach. The analysis focuses on system-level performance, material cost, scalability, and combined heat and power potential rather than heat to electrical conversion efficiency alone. Results demonstrate viable pathways for thermoelectric power generation in applications where durability, thermal utilization, and supply-chain resilience are critical.

System-Level Feasibility & Technical Evaluation

“Applied Thermoelectric Solutions was instrumental in shaping a comprehensive feasibility study for metallic solar thermoelectric generators, integrating technical performance, material cost, and sustainability considerations. Their work moved our concept from idea to practical evaluation and positioned us for prototype development and external funding.”

Diane Mero

Founder & CEO, STEMero

PowerBeam™ Wireless Power Transfer using Thermoelectric Generators (TEG)

PowerBeam™ explores thermoelectric power generation as a solid-state method for converting temperature differences directly into electrical energy. The project focuses on system integration, thermal coupling, and practical power output rather than laboratory efficiency metrics. This work demonstrates how thermoelectric generators can be engineered into robust, low-maintenance energy harvesting systems for distributed and infrastructure-scale applications.

How Thermoelectric Generators Work

Thermoelectric generators produce electricity by exploiting the Seebeck effect, where a temperature gradient across dissimilar materials generates an electrical voltage. By maintaining a hot side and a cold side, these solid-state devices convert heat directly into usable electrical power with no moving parts. This makes thermoelectric generators well suited for waste heat recovery, solar thermal systems, and environments where reliability and durability outweigh peak conversion efficiency.

Supporting Thermoelectric Generator (TEG) Research

Supporting research and technical studies focused on thermoelectric generator modeling, material selection, and system-level performance. This work provides the analytical foundation for designing reliable thermoelectric power generation systems for waste heat recovery, solar thermal integration, and distributed energy harvesting applications.

Battery & Advanced Thermal Management Projects

Projects focused on battery thermal management and advanced heat-transfer architectures for electric vehicles and energy storage systems. This work addresses high heat-flux removal, temperature uniformity, fast-charging enablement, and safety using solid-state and hybrid thermal management approaches at the cell, module, and pack levels.

Battery Thermal Management | The Breakthrough EVs Need

Battery thermal management is now the primary limiting factor for fast charging, range, safety, and battery life. Conventional cooling methods are approaching a physics ceiling because they depend on increasing the temperature difference between the cell core and surface. ParaThermic® High-Heat-Transfer (HHT) batteries overcome this bottleneck by reducing internal thermal resistance, enabling game-changing heat removal with the potential to transform electric vehicle performance.

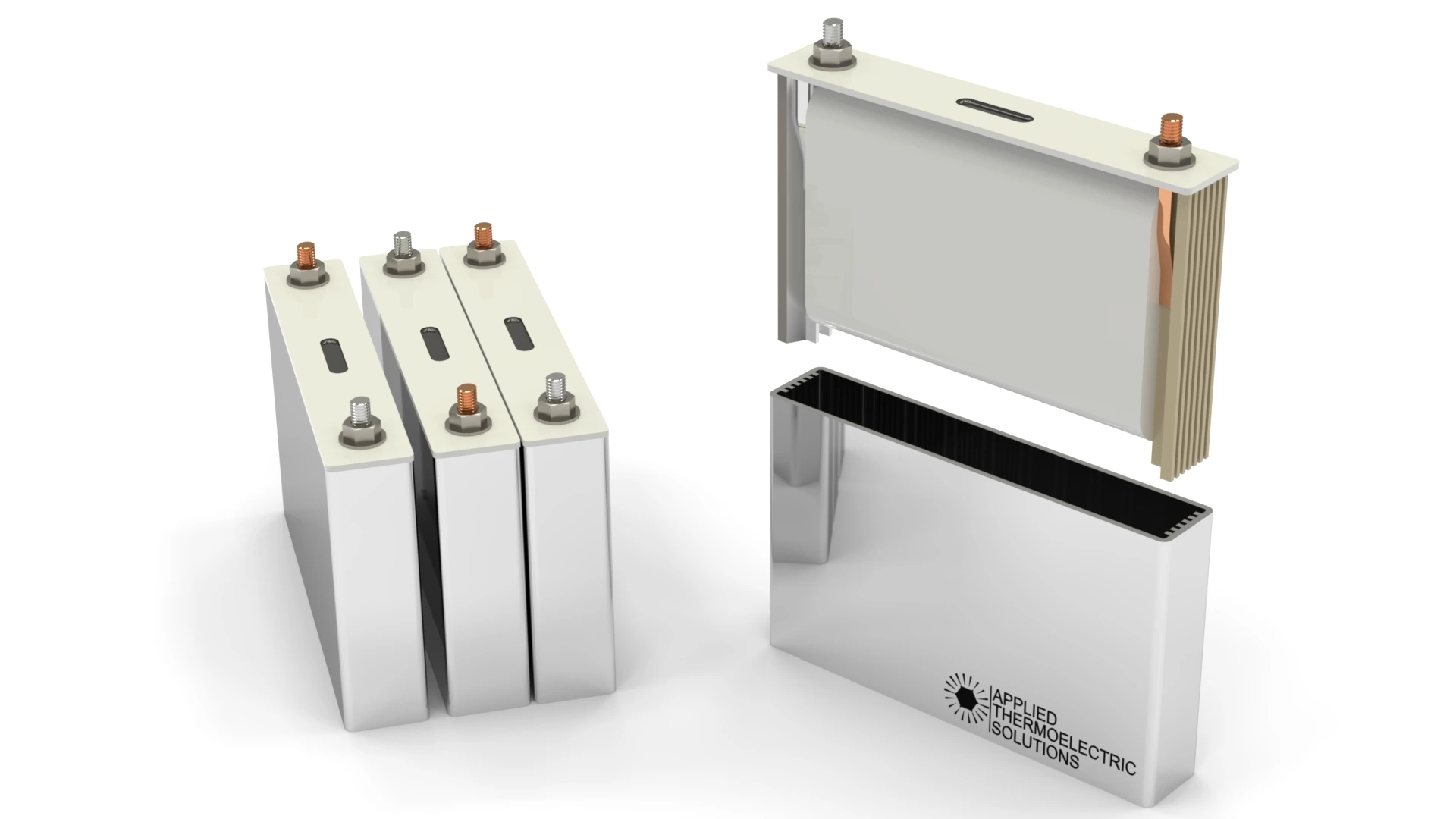

ParaThermic® High-Heat Transfer (HHT) Battery Technology

ParaThermic® High-Heat Transfer battery architectures integrate advanced thermal pathways directly into cell and pack designs to dramatically improve heat removal, battery and electric vehicle capability. These systems are engineered to extract heat faster than it can be generated during aggressive charging or thermal runaway, enabling safer operation, extended battery life, and game changing performance limits compared to conventional battery thermal management approaches.

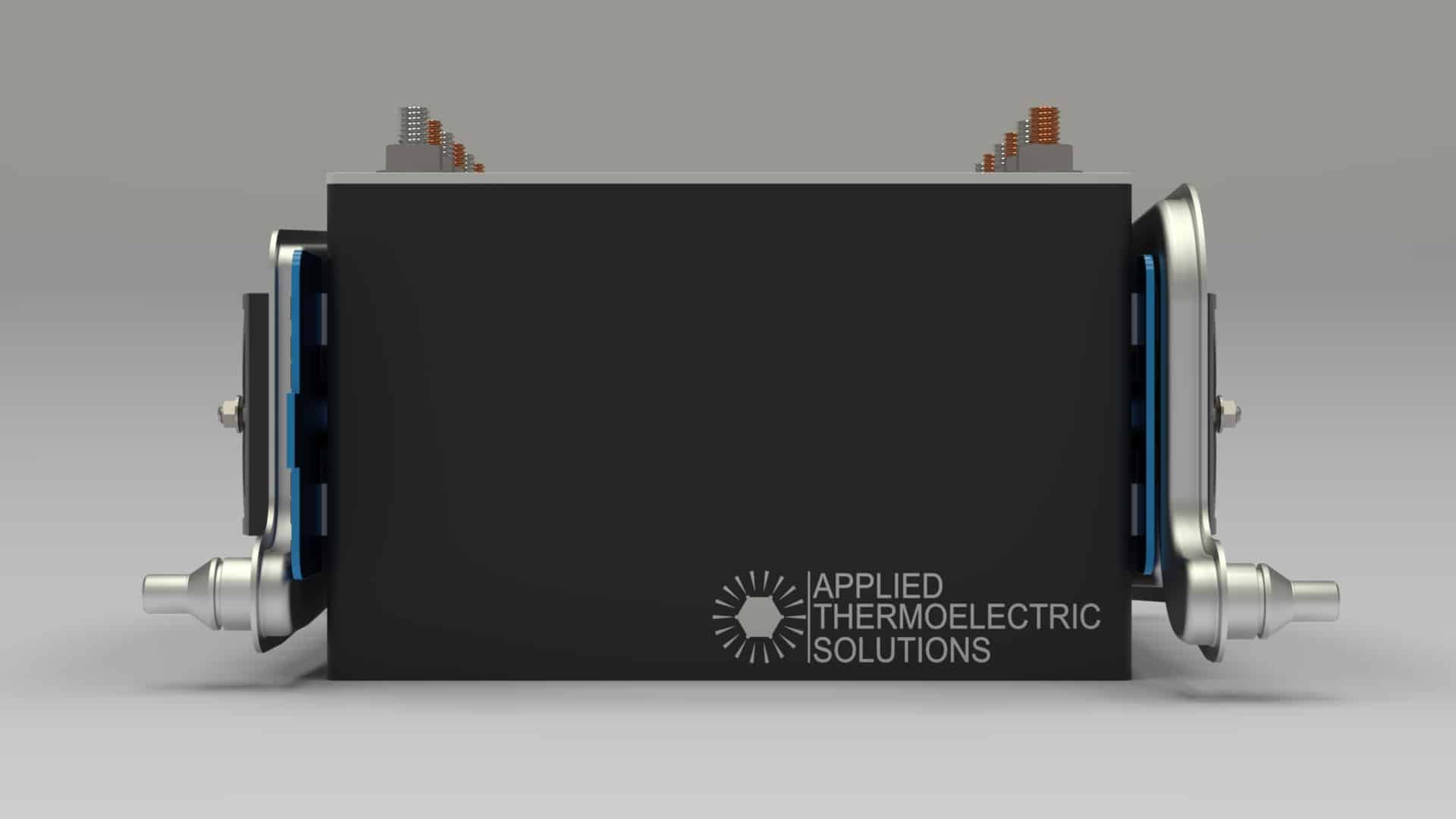

VoltaTherm® Battery Thermal Management

VoltaTherm® is an active battery thermal management system that uses thermoelectric cooling and heating to precisely control cell temperature under dynamic operating conditions. The system is designed for integration into battery packs where bidirectional thermal control, rapid response, and compact packaging are required to support performance, safety, and battery life.

Additional Battery Thermal Management Research

Supporting technical articles and analyses addressing thermoelectric battery cooling, heat spreaders, solid-state thermal pathways, and hybrid thermal architectures. These resources provide additional depth on the physics, design tradeoffs, and implementation considerations behind advanced battery thermal management systems.

Foundational Research and Technical Overviews

Foundational technical articles and research surveys that establish the underlying principles, applications, and system-level considerations of thermoelectric technologies. These resources provide engineering context and reference material supporting applied thermoelectric cooling, power generation, and advanced thermal management projects.

Introduction to Thermoelectrics and Medical Applications

A comprehensive introduction to thermoelectric principles and their application to medical cooling, heating, and power generation systems. This article surveys both commercialized and emerging medical uses of thermoelectric technologies, including solid-state cooling, temperature-controlled storage, wearable devices, and energy harvesting from body heat. It serves as a technical reference for engineers evaluating thermoelectrics in medical and biomedical applications.

Additional Text Links

Additional technical articles and project references providing deeper insight into thermoelectric system design, modeling, and application-specific trade studies. These links support the featured projects with detailed engineering context and background analysis.

Contributing Text Links

Additional technical articles and project references providing deeper insight into thermoelectric system design, modeling, and application-specific trade studies. These links support the featured projects with detailed engineering context and background analysis.

Awards and Technical Recognition

External recognition of Applied Thermoelectric Solutions’ technical contributions across thermoelectric engineering, innovation challenges, and industry engagement. These honors reflect peer-reviewed validation of the company’s applied research, system design expertise, and leadership within the thermoelectric community.

Recognitions and Industry Honors

External recognition of Applied Thermoelectric Solutions’ technical contributions and industry leadership.

Engineering Insight Beyond Components

“Applied Thermoelectric Solutions went beyond reviewing thermoelectric components, providing critical insight into overall system design and practical implementation. Their technical guidance significantly improved the final product and exceeded expectations.”

Finn Aretz

Operations Lead